Floating ball valves and trunnion ball valves are two popular designs used in various industries. Although they share many similarities, there are some key distinctions you should be aware of before making your selection.

Trunnion-mounted ball valves feature a stem on one side and an attached trunnion on the other. This design helps keep the valve securely closed during high pressure or surges of fluid.

Table of Contents

ToggleDelving into Floating Ball Valves: A Cost-Effective Solution

Floating ball valves are renowned for their simple yet effective design, making them a cost-effective choice for a variety of applications. Their ball-shaped element, aptly termed the “floating ball,” is supported by upstream and downstream seals, ensuring tight sealing and preventing leakage.

Advantages of Floating Ball Valves:

- Cost-Effective: Their straightforward design and manufacturing process translate into lower production costs.

- Ease of Maintenance: Fewer internal components simplify maintenance procedures.

- Versatility: Suitable for both low- and moderate-pressure applications.

Trunnion Ball Valves: Embracing Durability and High-Pressure Applications

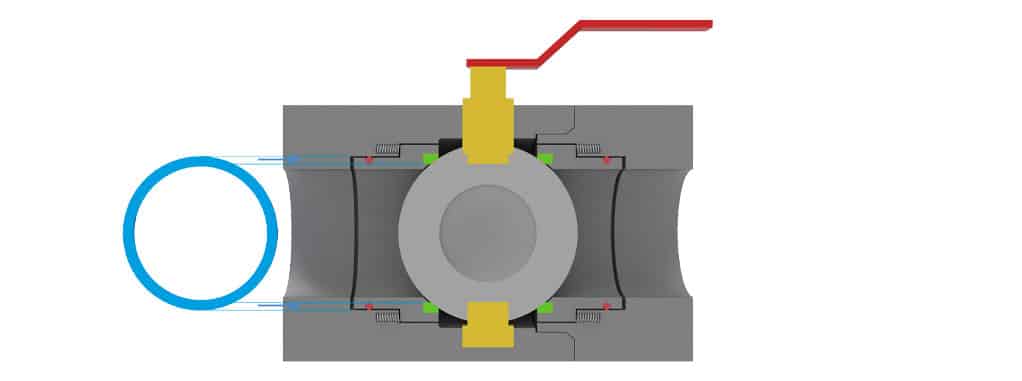

Trunnion ball valves excel in high-pressure environments, where their robust design ensures reliable operation and extended valve life. The ball is securely supported by a trunnion, a metal shaft that prevents excessive movement and ensures proper sealing even under extreme conditions.

Advantages of Trunnion Ball Valves:

- Exceptional Durability: Their robust design withstands high-pressure applications and harsh media.

- Superior Sealing: The trunnion support minimizes ball movement, enhancing sealing integrity.

- Adaptability: Capable of handling both low- and high-pressure applications.

Operational Nuances: Floating Ball Valves vs. Trunnion Mounted Ball Valves

Floating ball valves and trunnion-mounted valves both feature a rotary ball that rotates to stop or start flow. Their operation and design criteria differ based on pressure, class, bore size, and other variables.

Trunnion ball valves are more common than floating valves and are designed for larger pipeline sizes and higher-pressure conditions (class 600 or above). They feature a two-piece body design with the trunnion on one end, stem at the other, and bearing in between.

The trunnion is designed to securely hold the ball in place and prevent any lateral movement. This ensures proper valve seals on both sides, especially for multiple-port and low-pressure applications. Furthermore, its seat is energized by upstream pressure to force the ball into its seat for positive closure.

Diverse Applications of These Two Kinds of Ball Valves

Floating ball valves are a popular choice in industrial applications, particularly gas and liquid systems. Their dual-directional seals enable pressure and temperature regulation.

They are commonly employed in water systems to maintain high pressure and prevent air pockets from forming. They can be operated manually or with an actuated power source such as pneumatics, hydraulics, or electricity.

Trunnion ball valves lack a support structure, allowing them to float freely within the medium they regulate. This makes them more adaptable and suitable for various applications.

Xintai Valve Company produces a wide range of valves, such as check and swing gate valves. Their products are used in various industries like chemical, petroleum, electrical power, and metallurgy.