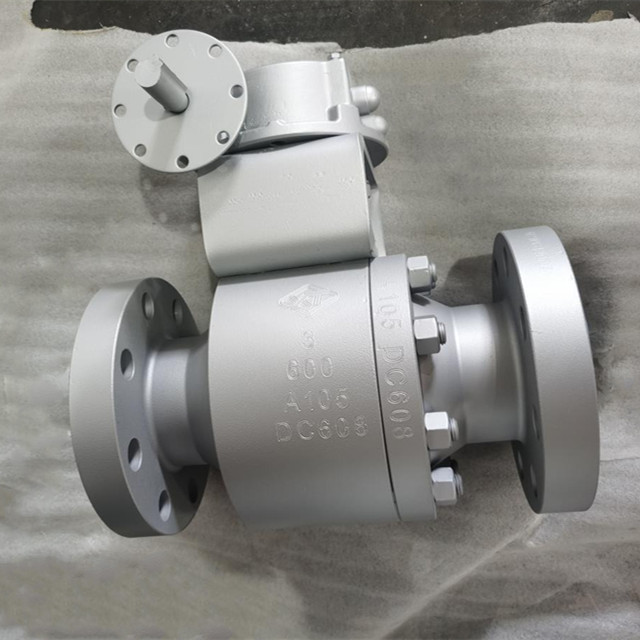

Floating ball valves are an industry standard for regulating flow in piping systems. They are composed of two concave seats that sandwich a ball inside. The seats do not move, creating a tight seal. The actuation shaft is not fixed to the ball; instead, it pivots as the ball axis rotates. The valves are also equipped with stem packing, which prevents leakage through the interface between the bonnet and the stem.

A floating ball valve is an important component in any hydraulic system. Unlike a conventional valve, a floating ball valve is made of two cupped seats and a stem. The internal ball is freely suspended in the water. This design provides a good seal between the ball and the valve body. Floating ball valves can be bidirectional, but they are difficult to operate in high-pressure situations.

Floating ball valves are a very common type of ball valve in toilet tanks. If you want to know more about a floating ball valve, continue reading this article.

Table of Contents

ToggleWhat Is a It?

A floating ball valve uses elastomeric seats to control fluid flow. The ball is squeezable toward the valve’s elastomeric support. This allows the ball to float. A floating ball valve can switch between an open and closed state. The valve shaft can only move 90 degrees. In addition to the basic features, floating ball valves can be customized with add-ons like O-rings or extra packing.

A floating ball valve is different from a traditional one in that it has a ball-shaped structure that stays in the liquid it is placed in. Instead of a flange or other mechanical device, the floating ball valve has two elastomeric seals that seal the valve. The seats keep the floating ball in place and provide a tight shutoff when the valve is turned off. When the valve is turned on, the ball has moved a fraction of an inch laterally and closes the fluid flow.

Advantages of a Floating Ball Valve

There are several advantages of a floating ball valve over its competition. Its size is small, and its weight is low, which is a plus for those who want to save on weight and space. Whether you’re looking for a valve that will be easy to install and use or you’re looking for a valve that’s a good investment, floating ball valves have some important advantages to offer.

First, a floating ball valve is easy to operate as you just need to turn the handle quarterly. The simple structure and lightweight design make it easy to use. It also has small fluid resistance and is reliable.

Floating ball valves can be used in many applications, including complex applications involving high temperatures and pressures. When choosing one, take into account the type of seal used and whether the valve is a two-piece valve. The advantages of a floating ball valve can’t be matched by any other type of valve.

Another advantage of a floating ball valve is its easy installation and low maintenance. The floating ball valve uses a sphere-like ball that floats slightly in a liquid, allowing it to open and close when needed. The float-ball ball valve offers a failsafe and simple mechanism, making it an excellent choice for many applications. A floating ball valve is also very economical and lightweight, making it an excellent choice for many applications.