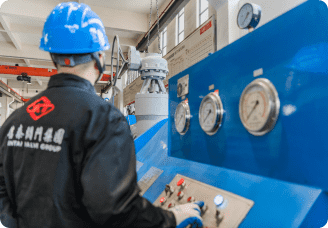

Quality control

Providing high-quality products, the company configured advanced detection equipment and perfect testing methods, establishing a strict quality management team to achieve the raw material testing, production process testing, product and application of the entire process of quality control.

Strictly control the production process testing to ensure the safety and reliability of the project system.

Accurate control, to ensure the quality of products without defects

Optimizing and solving the corresponding problems in the application of the valve.

We design, engineer and produce your tailor-made valves.

Company Profile

Our Engineering Department has great experience in the production of valves for severe applications and provides our clients with technical solutions, especially in XINTAI forging valves and cryogenic valves.

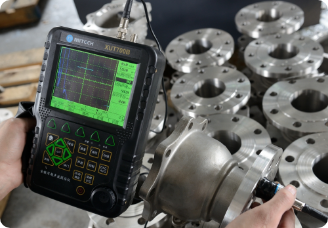

Material Detection

XINTAI competitive advantage is the completer testing facilities which we have continued to invest in for years. These facilities are really important in the stress tests of the finished components/products and those in the design phase.

Technology Innovation

We apply advanced computer simulation analysis technology to analyze the parameters (like stress, temperature and flow field) and their distribution, to evaluate the service performance of valves under work conditions, to optimize and solve the possible problems in the application of valves. With these efforts, we guarantee the performance of products from the source and transfer the maximum value to clients.