Daftar isi

BeralihPeriksa katup are like traffic directors for fluids in systems, ensuring they only flow in one direction.

They’re super important in places like pump outlets, pipelines, and compressors, keeping equipment safe by stopping fluid from flowing backward.

This prevents issues like water hammering caused by sudden pressure changes. There are different types of check valves, each with its unique features.

This guide explains what check valves are, what they do, their different parts, and types, and how they work.

Define Check Valves: What to Know About Them

A check valve, often referred to as a non-return valve, retention valve, or one-way valve, serves as a critical component allowing fluid to flow in only a singular direction.

Comprising two openings or ports—the inlet, where fluid enters, and the outlet, where fluid exits—the check valve plays a pivotal role in preventing the undesirable reversal of fluid flow, known as backflow, in the applied system.

Its application is particularly essential in scenarios where backflow could compromise the integrity of the incoming fluid.

The functionality of a check valve hinges on the dynamics of pressure within the system.

It opens to facilitate flow through the inlet when the pressure at the inlet surpasses that at the outlet.

Conversely, it swiftly closes to impede flow when the outlet pressure exceeds that at the inlet.

The closure mechanism may also involve the check valve’s weight, a spring, or alternative methods, depending on the specific valve type.

Notably, these valves operate autonomously, being activated by changes in pressure, and are typically devoid of manual controls such as handles or stems.

These valves operate automatically based on pressure changes and usually do not have handles or stems, emphasizing their reliability in preventing backflow in various applications.

What Does a Check Valve Do?

Check valves, designed for unidirectional fluid flow, automatically respond to fluid pressure, opening to permit flow or closing to prevent reverse flow. These valves play crucial roles in various applications:

Preventing Backflow in Pipeline Systems

Check valves to ensure fluid moves in one direction, preventing undesirable backflow that can lead to system contamination and damage.

Safeguarding Pumps and Generators

They protect pumps and generators by preventing reversal and maintaining the intended flow direction.

Halting Backflow from Containers

Check valves to stop undesired backflow from containers, maintaining the integrity of the system.

Backflow can result in contamination, water hammer, and system damage.

Specific types, like the stop check valve and foot valve, offer additional functions beyond backflow prevention.

For instance, the stop check valve serves as a throttle or isolation check valve, while the foot valve blocks debris from advancing in the pipeline.

In certain scenarios, check valves, such as the non-slam check valve, act as auxiliary systems to address pressure increases above the main system pressure, effectively preventing water hammer.

The absence of a check valve in systems experiencing backflow can lead to water hammer, causing destructive impacts on pipeline components.

Applications: Where or What is a Check Valve Used For?

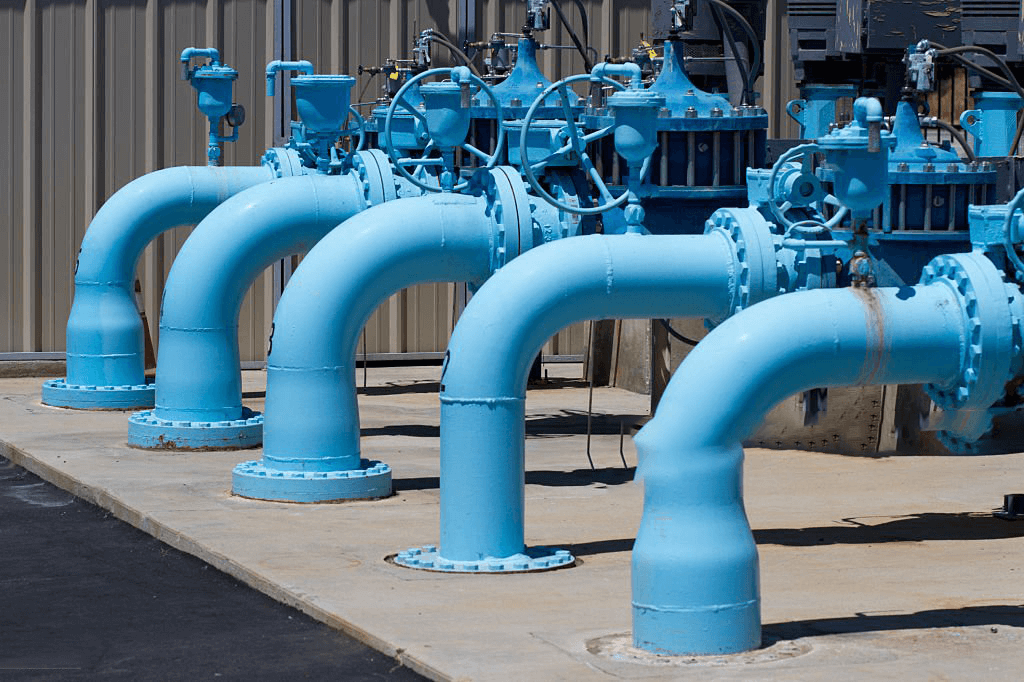

Check valves find diverse applications across various industries due to their essential role in controlling fluid flow. Some key applications include:

Pipelines and Plumbing Systems

Check valves are extensively used in pipelines and plumbing systems to prevent backflow.

They ensure that fluids move in a designated direction, preventing contamination and damage to equipment.

Water and Wastewater Treatment

In water treatment plants, check valves are employed to manage the flow of water and prevent backflow.

They play a crucial role in maintaining the integrity of water and wastewater treatment processes.

Industri Minyak dan Gas

Check valves are integral in the oil and gas sector for controlling the flow of fluids in pipelines.

They prevent the reverse flow of oil and gas, safeguarding equipment and ensuring efficient operations.

Pembangkit listrik

Check valves are utilized in power generation facilities, including nuclear, thermal, and hydropower plants.

They help control the direction of fluid flow, ensuring the smooth functioning of turbines and other equipment.

Pemrosesan Kimia

Check valves play a vital role in chemical processing industries, where precise control of fluid flow is crucial.

They prevent the backflow of chemicals, maintaining safety and efficiency in the processing of various substances.

Sistem HVAC

Heating, ventilation, and air conditioning (HVAC) systems incorporate check valves to regulate the flow of fluids.

They contribute to the efficient operation of HVAC equipment and prevent issues related to backflow.

Marine and Offshore Applications

Check valves are employed in marine and offshore environments to control the flow of fluids on ships, offshore platforms, and related infrastructure.

They contribute to the safety and reliability of marine systems.

Common Types of Check Valves

Check valves, vital in controlling fluid flow and preventing backflow, come in various types, each serving unique purposes:

Katup Periksa Ayun

Considered the most common type of check valve, swing check valves operate with a swinging disc to control fluid flow based on pressure differentials.

Katup Periksa Angkat

Installed horizontally, vertically, or angularly, it uses a lifting disc controlled by inlet pressure.

Katup Periksa Pelat Ganda

Compact and robust, it handles substantial backflow in industrial settings.

Katup Periksa Non-Slam

Mitigates water hammer through a spring-assisted closing mechanism, preventing pressure spikes.

Katup Periksa Wafer

Slim and lightweight, it uses swinging discs similar to butterfly check valves.

Diaphragm Check Valves

Utilizes a rubber diaphragm to flex open under increased pressure, preventing backflow.

Spring Loaded In-line Check Valve

Requires sufficient inlet pressure to open, preventing water hammer.

Spring Loaded Y-Check Valves

‘Y’-shaped with an angled spring, offers serviceability while connected to the system.

Stop Check Valve

Combines blocking and throttling functions, ideal for steam operations.

Ball Check Valve

Employs a spherical ball to seal and control fluid flow based on pressure differentials.

Foot Valve

Used in suction line operations, featuring a strainer to prevent clogging.

Duckbill Valve

Resembles a duck beak, allowing fluid flow with increased pressure and closing during backflow.

Tilting Disc Check Valves

A modification of swing check valves, this valve type opens at lower pressures due to a pivoting disc.

Global Check Valve Supplier: About Xintai

Established in 1998, XINTAI Valve Group Co., Ltd. has emerged as a leading force in the valve manufacturing industry.

Located in the Longwan Konggang New District of Wenzhou, the group operates with cutting-edge technologies across four manufacturing bases, housing eight advanced casting production lines within a spacious 32,000-square-meter workshop.

Boasting an annual production exceeding 270,000 valves since the establishment of its casting factory in 1998, XINTAI has become one of Wenzhou’s largest casting valve manufacturers.

Dedicated to quality, the company holds certifications such as ISO9001, domestic TS security, CE, OHSAS18001, and API, ensuring adherence to industry standards.

With a focus on leading forging processes, XINTAI crafts robust valves suitable for high-pressure and high-temperature systems.

The company offers a diverse range of custom valve solutions, encompassing katup kontrol, cryogenic valves, katup gerbang, globe valves, katup bola, check valves, Katup kupu-kupu, and more.

With strategic offices, marketing centers, and an inspection center, XINTAI remains a reliable and innovative player in the global industrial valve manufacturing sector.

Kontak Xintai today to jumpstart your fluid control solution.