Inhaltsverzeichnis

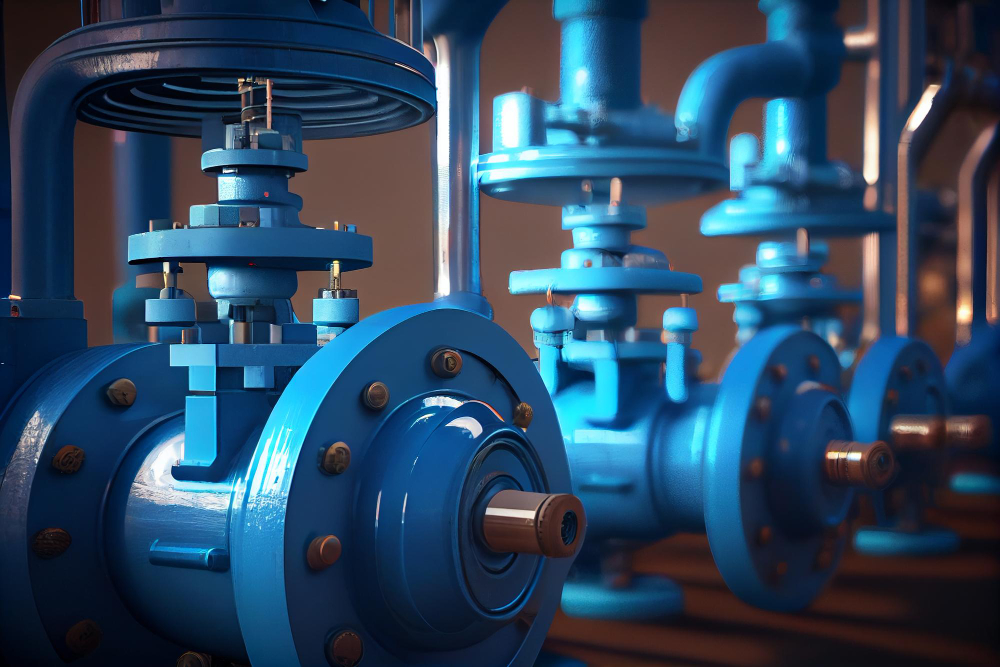

UmschaltenSchieber have been industrial workhorses for well over a century, and for good reason. Their simple yet robust design provides reliable isolation for pipes carrying liquids, gasses, and slurries in countless applications across many sectors. When these rugged valve bodies are topped with flanged end connections, it creates a highly versatile package.

- Flanged connections allow easy installation between piping sections

- Wedge gate provides full-bore, unrestricted flow path when open

- Bidirectional sealing prevents backflow in either direction

Flanged gate valves offer an excellent blend of durability, ease of maintenance, affordable pricing, and space-saving layout potential. While they do have some limitations, their straightforward construction minimizes potential issues.

If you need an on/off isolation valve that gets the job done without the complexities, flanged gate valves could be the perfect solution.

Flanged Gate Valve – An Overview

What are the characteristics of flanged gate valve?

At its most basic, a flanged gate valve consists of just two body sections bolted together. The body cavity contains a wedge-shaped gate that drops into the bottom section to open or lifts perpendicularly into the upper section to close.

All gate motion occurs by way of a stem that extends up through the valve body and connects to a handlever, gearbox, or actuator mounted topside. Turning the stem raises or lowers the gate between the two parallel seats machined into the body sections.

Full-Bore Flow Path

When fully open, the gate drops completely out of the flow path leaving an unobstructed, full-bore passage for media. The bore diameter matches the inner diameter of the connecting pipe with no restrictions, minimizing pressure drop and flow turbulence.

This design allows flanged gate valves to offer higher flow capacities compared to globe or other valve types. It also helps reduce valve erosion from high-velocity flow.

Bidirectional Shutoff Sealing

Another advantage is that the gate seals equidistantly against both upper and lower body seats. This bidirectional shutoff prevents backflow and seepage in either direction when closed – an important safety feature.

The seats themselves contain either metal-to-metal sealing surfaces or reinforced gaskets, seals, or coatings. These must be carefully matched to the gate and body materials to handle the pressure, temperature, and media chemistry.

Flanged End Configurations

As the name implies, flanged gate valves feature raised face or ring-type flanges on each end to bolt directly between mating pipe flanges. Some of the most common flange facing styles include:

- Raised Face (RF) – Raised surface machined on the flange face

- Flat Face (FF) – Smooth planar flange face surface

- Large/Small Groove – Concentric grooves cut into flange face

- Ring Type Joint (RTJ) – Raised circular section on the flange face

In addition to flanges, gate valves may also come in other common end styles like:

- Threaded (NPT)

- Socket Weld

- Butt Weld

The flanged configuration allows for easy installation into new piping runs or removal for maintenance and replacement.

How is a Flanged Gate Valve Constructed?

To withstand the demanding conditions of industrial service, valve bodies are manufactured from sturdy metallic materials:

- Kohlenstoffstahl – Cost-effective, general-purpose option

- Edelstahl – Offers exceptional corrosion resistance

- Nickel Alloys – Superior strength at extreme temps

- Bronze – Durable yet economical for lower pressures

The body material selection depends on the temperature, pressure, and media properties. It must provide sufficient structural strength as well as chemical compatibility with the process contents.

Additional components like the gate wedge, stem, seat surfaces, and seals/gaskets utilize materials customized for each operating environment.

Applications and Industry Use

The simple, versatile flanged gate valve design lends itself well to use across a broad spectrum of industrial sectors. Here are just some of the most common application areas:

- Öl und Gas – Upstream, midstream, and downstream operations

- Petrochemical – Refineries, chemical plants, storage terminals

- Energieerzeugung – Fossil fuels, nuclear, renewables

- Pulp and Paper – Washers, digesters, chemical handling

- Mining – Slurry lines, dewatering, tailings

- Water/Wastewater – Treatment facilities, large distribution lines

- Nahrungsmittel und Getränke – Ingredient lines, CIP, utility distribution

- General Manufacturing – Isolation for processing equipment

Flanged gate valves can reliably handle liquids, gases, abrasive slurries, and everything in between. Their economical pricing also makes them a popular choice for large piping distribution networks and lower-cost installations.

What Flanged Gate Valves Do Best

While highly versatile, flanged gate valves do have some limitations in terms of operation and flow control capabilities:

- Best Use – On/Off Isolation Duty

With their straight open/close operation, flanged gate valves truly shine as on/off isolation valves. The gate’s perpendicular motion provides a tight shutoff with bidirectional sealing to block flow in either direction.

- Limited Flow Throttling Ability

Because the gate passes through the flow path when opening/closing, throttling flow is not recommended. The gate can vibrate and face accelerated wear if passing through partially opened positions repeatedly.

- Not for Frequent Cycling

While robust overall, the sliding surfaces that seal the gate inevitably face wear and friction over long operating cycles. It’s best to limit flanged gate operation to just a few cycles per year.

- Still an Economical Choice

Despite these functional limitations, flanged gate valves continue delivering outstanding value. Their reliable performance and affordable pricing keep them popular across heavy industrial and municipal piping systems. As long as you don’t need frequent operation or modulation, they’re a great choice.

Abschluss

While their operation and capabilities are somewhat limited, flanged gate valves continue delivering outstanding value across industry. For reliable on/off isolation at an economical price point, they are tough to beat.

When you depend on your pipeline distribution and processing equipment, a proven name like Xintai-Ventil can provide the flanged gate valve solutions you need with complete confidence. With a commitment to innovative engineering and the strictest quality controls, Xintai produces valves trusted by leading companies worldwide.