Thread Ball Valve Collection

Threaded ball valves feature internal and external threads. These threads facilitate the connection between the inlet and the outlet of a valve. However, threads on ball valves can also be damaged by fluids. In order to avoid damage, check the manufacturer's history and certifications. Many threaded ball valve manufacturers have minimum order quantities. Make sure to check these guidelines before ordering. The cost of threaded ball valves varies based on quality, grade, and quantity. Standard threaded ball valves are more affordable than custom-made ones. When comparing threaded ball valve prices, remember to take your specific project requirements into account.

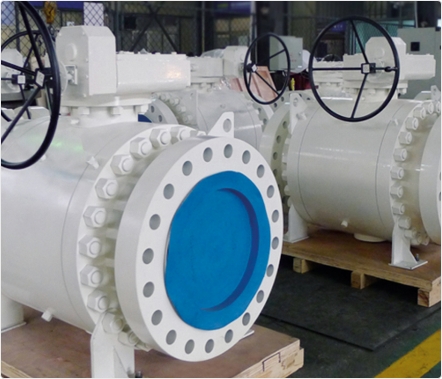

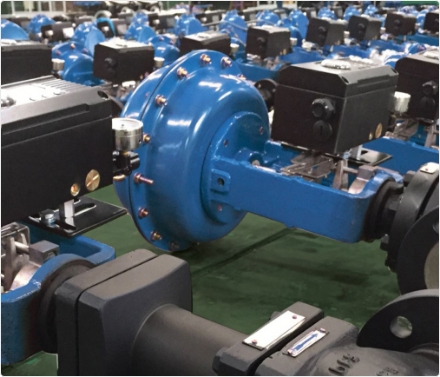

Ball Valves

Thread Ball Valve Manufacturing

About XINTAI VALVES Manufacturer

XINTAI VALVE GROUP CO., LTD. was founded in 1998, is a professional industrial ball valve manufacturing company that conjoins R&D, casting, development, production and sale. The Group's headquarters is located in the Longgang Airport New District, Wenzhou, and is centered on research and manufacturing technology.

The factory covers an area of approximately 30,800 square meters. The two major bases for casting were respectively located in the central industrial zone of Longwan District, Wenzhou, with an area of 9,800 square meters. Longwan Airport New Area Casting Base in Wenzhou, with an area of 28,000 square meters. The existing staff of 578 people, including high and mid-level engineering and technical personnel 58 people, mainly in oil, natural gas, chemical, power stations, metallurgy, national defense, water conservancy projects, pharmaceuticals and other fields.

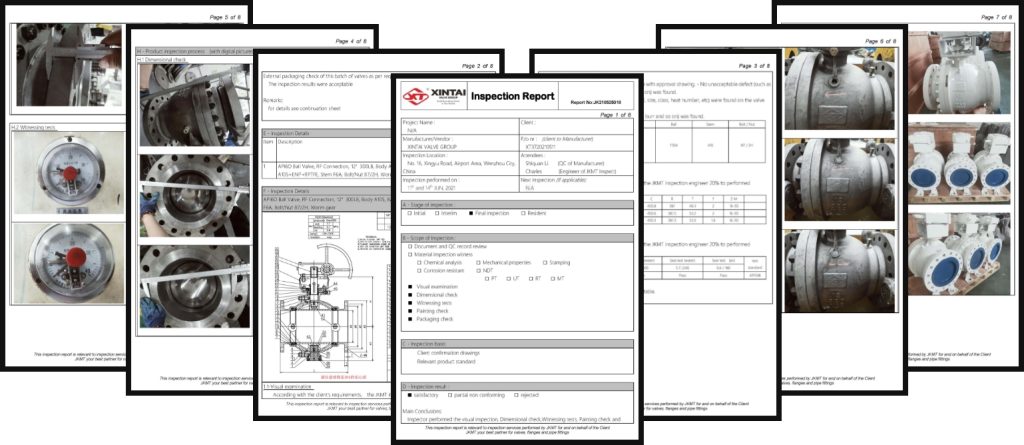

Thread Ball Valve Inspection Report

We will issue an inspection report like this before all orders ship. The basic inspection steps include a visual examination, dimension check, witnessing test, painting check, packaging check, then issuing the finished test report. We can also carry out special tests according to customer requirements.

Our Team

We Will Serve You With The Best of Our Capacity By Expert Team

We are prestigious industrial Thread Ball Valve manufacturer and supplier of Industrial Casting Ball Valves in Wenzhou.

XINTAI is registered with the following governmental agencies:

American Petroleum Institute(API) No. 6D-1778

Quality Management System Certificate of Approval (ISO9001:2015)

Certificate of Quality System Approval(CE) No. HPiVS-IP1001-015-Q-04-00

Certification of Registration( OHSAS18001) No.86185710109S

We design, engineer and produce your tailor-made valves.

The Best Solution for Oil& Gas industry

Serving an impressive list of long-term clients with experience and expertise in industries.

What Are Threaded Ball Valves?

A threaded ball valve is a type of valve that comes with a threaded connection. These valves are easy to install and fairly inexpensive. They're best for smaller applications because they have smaller diameters.

When used in larger applications, they are more prone to leaks through the threads. To prevent leaks and protect against galling, you can use pipe tape to seal the threads. The proper sealant will prevent any metal-to-metal contact and will also prevent galling.

These valves are available in three common designs, i.e., male x male, female x female, and male x female. Before installing a threaded ball valve, you should always clean its ports and seat to remove any foreign particles. Clean the threads as well. If any metal shavings are present, you can use a high-quality pipe thread sealing compound or PTFE thread sealing tape. This step will ensure that your valve is leak-proof.

A threaded ball valve provides a tight connection and is the most common type of connection used in ball valves. It offers a tight seal between the valve and the pipe. Most of the ball valves incorporate threaded connections.

What Thread is on a Ball Valve?

A threaded valve connection provides a tight, streamlined seal. A female threaded valve connection fits over a male threaded pipe. Here are the two types of threads used on ball valves.

- Straight Thread

The threads on a ball valve can be either straight or tapered, and they differ in their diameter. Straight threads usually require an O-ring for sealing, while tapered threads do not. Pipe tape can be used between the female and male threads to provide lubrication and sealing and to prevent metal-to-metal contact. Threads are classified according to their dimensions in international standards. When choosing a threaded ball valve, check its rating. This specification is important because a threaded valve cannot absorb gaps or distortion in the pipe. Moreover, a straight-threaded valve may develop leaks if the pipe has been dismantled.

- Taper Thread

Another type of thread used in ball valves is taper thread. This type of thread connection tapers towards the end. The best thing about this thread connection is that it doesn't require an O-ring seal. However, you will still need sealant and pipe tape to get the best seal. This way, there will be no leakage when you use the ball valve. When selecting threads for a ball valve, it's best to use a caliper to determine the diameter of each. Some tapered valves use pipe tape between the male and female threads to serve as lubricant and sealing and help prevent metal-to-metal contact.

Contact Us

If you want to get a quotation or more product details, please leave us a message.