Ball Valve Collection

Ball valves have been in existence for more than 125 years. Presently, there are 4 types of ball valves used in controlling the flow of gas or liquid. Choosing the right ball valve is what is most important/ if you choose a ball valve allows too much or too little flow, you can wear and tear the valves. In order to maintain a smooth flow, you must choose the right ball valve. Each ball valve comes with different uses, capacities, and characteristics. For instance, different ball valves can transport sludge, gases, liquids, vapors, etc. This guide contains crucial factors that will assist you to select the best ball valve that will serve you for many years without having to incur regular replacement costs.

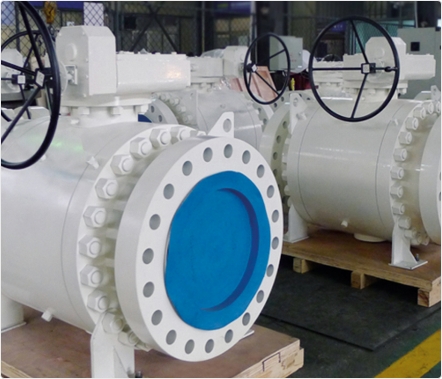

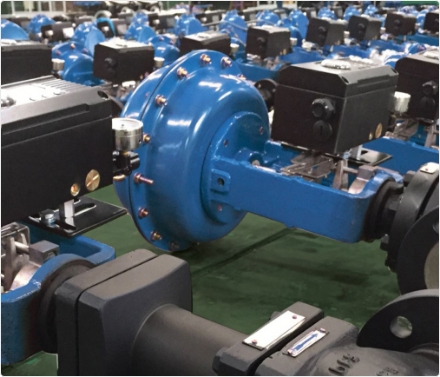

Ball Valves

Ball Valve Manufacturing

About XINTAI VALVES Manufacturer

XINTAI VALVE GROUP CO., LTD. was founded in 1998, is a professional industrial ball valve manufacturing company that conjoins R&D, casting, development, production and sale. The Group's headquarters is located in the Longgang Airport New District, Wenzhou, and is centered on research and manufacturing technology.

The factory covers an area of approximately 30,800 square meters. The two major bases for casting were respectively located in the central industrial zone of Longwan District, Wenzhou, with an area of 9,800 square meters. Longwan Airport New Area Casting Base in Wenzhou, with an area of 28,000 square meters. The existing staff of 578 people, including high and mid-level engineering and technical personnel 58 people, mainly in oil, natural gas, chemical, power stations, metallurgy, national defense, water conservancy projects, pharmaceuticals and other fields.

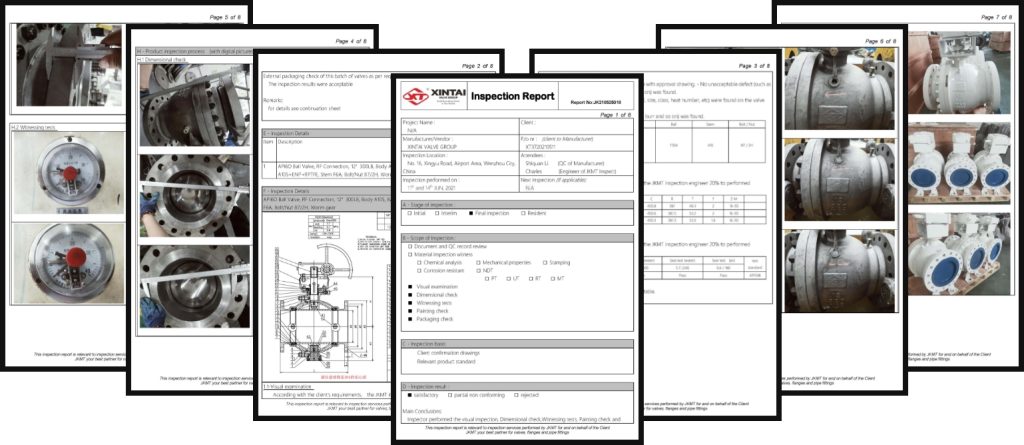

Ball Valve Inspection Report

We will issue an inspection report like this before all orders ship. The basic inspection steps include a visual examination, dimension check, witnessing test, painting check, packaging check, then issuing the finished test report. We can also carry out special tests according to customer requirements.

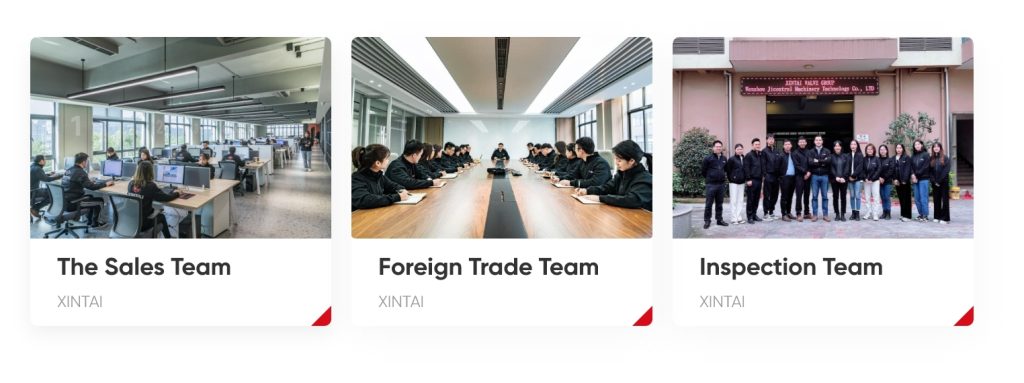

Our Team

We Will Serve You With The Best of Our Capacity By Expert Team

We are prestigious industrial ball valve manufacturer and supplier of Industrial Casting Ball Valves in Wenzhou.

XINTAI is registered with the following governmental agencies:

American Petroleum Institute(API) No. 6D-1778

Quality Management System Certificate of Approval (ISO9001:2015)

Certificate of Quality System Approval(CE) No. HPiVS-IP1001-015-Q-04-00

Certification of Registration( OHSAS18001) No.86185710109S

We design, engineer and produce your tailor-made valves.

The Best Solution for Oil& Gas industry

Serving an impressive list of long-term clients with experience and expertise in industries.

Advantages of Using Ball Valves in Industrial Applications

They are budget-friendly as compared to other valves.

They come with a low-maintenance and compact design that doesn’t need lubrication.

Ball valves are made using durable and corrosion resistant materials, which increases their life span.

They aren’t prone to leakages.

They are flexible since they come in multi-way designs.

Ball valves close and open quickly.

Disadvantages of Using Ball Valves in Industrial Applications

They aren’t ideal for irreversible throttling.

In case of residual fluids, the particles in the fluid collide with the valves’ surfaces, them to stick on the surfaces, causing abrasion, leakage, and other issues.

Factors to Consider When Buying Ball Valves

- Media Passing Through the Ball Valves

Specific control systems and applications are suitable for certain liquids. There are some ball valve systems that are tasked for the smooth flow of chemicals in enormous industries. Others handle water flowing from reservoirs and dams, directing it to various hydroelectric plants. Some special ball valves are manufactured to prevent radioactive wastes from leaking.

Consider the media that is to be circulated in the ball valve: is it a liquid or a gas media? Is this media a food product, chemically neutral, a medical fluid, or corrosive, requiring extraordinary hygiene conditions?

All these factors are helpful in choosing the materials used in the manufacture of the ball valves that will suit your needs. Additionally, it ensures the safety of the people working with the ball valves and the connecting systems.

- Working Pressure

Ball valves are designed to handle great liquid pressures. It’s important to determine the pressure range that flows through the ball valves; this helps you to choose the right valve that can comfortably handle this pressure.

- Temperature Range Flowing through the Ball Valves/ Materials Used

Ball valves are used in handling cold and hot fluids. It’s essential to determine the coldness or hotness of these fluids that flow the ball valves. It’s particularly helpful in choosing the particular make of the ball valve to purchase. Valves are made using different manufacturing materials such as PVC, stainless steel, and ceramic. Each of these materials is suitable for different temperatures.

For efficiency and safety, the manufacturing materials must be compatible with pressure and temperature ratings, and the chemical constitution of the liquid or gas that flows through your ball valve. You must also consider the soft sealing materials used in the valves. One of the most common is P.T.F.E; it’s a chemically inert material that’s used for sealing the valves and it’s compatible with almost all media types.

- The Volume of the Fluid Flowing through the Valve

Different ball valves can manage different volumes of liquids flowing through them. It’s essential to determine the fluid volume that will flow through the ball valve to choose the correct size that can handle the volume comfortably.

- Cost

After considering the 4 factors – Fluid volume, fluid type, temperature, and working pressure, you must consider the cost of the ball valve. The cost of ball valves is associated with the materials used in their manufacture and their sizes. Also the valve’s brand affects the cost. There are several companies that manufacture ball valves and many of them have websites where you can view the prices online before making your decision.

- Uses

Before choosing a ball valve, it’s important to be sure about its uses. Do you intend to use it stop the flow of a fluid or regulate its flow? Different ball valves have different uses, which makes it important to be sure of their intended uses before making your purchase.Ball valves come with different configurations; this makes it important to have a clear understanding of the work at hand to ensure that the ball valve you buy is an excellent fit for the job at hand.

- Operating System

Consider the ball valve’s operating system; is the valve powered automatically or operated manually? If it’s a manual ball valve, you must be on-site to operate it, whereas in automatically powered valves, you can operate them manually.

- Installation Cost

Choosing the best ball valve to be incorporated in your flow systems is also determined by the installation cost. This factor is directly connected with the required workforce in the valve’s installation process and any other related components. The cost of installing the ball valve also depends on whether the required workforce will be within the company (internal) or from other installers (external).

Also, it’s important to consider how the ball valve will be incorporated into your system and the kind of installation and assembly to be used. Will it need to be bolted through the flanges, screwed in, or welded?

- How will the Ball Valve be powered?

Ball valves can be operated by powering them using different methods. It’s important to determine which method is most convenient for you. Some of these methods include:

- Manually operated ball valves have levers and handles and are most suitable for off/on applications that are controlled by the operator. Since these ball valves must be operated manually, they aren’t suitable for use in high-cycle applications.

- Air-filled ball valves are ideal for applications that can access compressed air or/and need high durability and quick cycle times.

- Electric ball valves are ideal for applications with slower cycle speeds and time or those that can’t access compressed air. They are also referred as motorized ball valves.

- Hydraulic ball valves are similar to the air-filled ones. However, liquids can’t be compresses since they provide extra torque output. Hydraulic valves are more expensive and may need several additional components for them to function properly.

Contact Us

If you want to get a quotation or more product details, please leave us a message.