About Us --

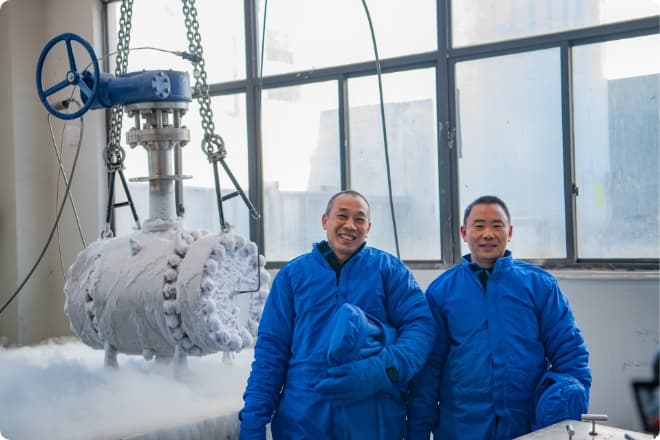

China Industrial Valve Manufacturer

XINTAI VALVE GROUP CO., LTD.was founded in 1998, is a professional valve maunfacturing company which conjoins R&D, casting, development, production and sale. The Group’s headquarters is located in the Longwan Konggang New District, Wenzhou, and is centered on research and manufacturing technology.

Leading Forging Process

Great strength forging valves will make them ideal for systems with high-pressure and high-temperature requirements.

View More >>Accredited Quality

We have passed ISO9001 quality management system certification, domestic TS security certification, CE, OHSAS18001, API.

View More >>Custom Valve Solutions

As an industrial valve manufacturer, XINTAI's casting industry valve and gate valve are trusted by industries worldwide.

View More >>

Industrial Valve Supplier

We manufacture trusted, high-quality industrial valves

Full Service

We are providing high-quality industrial valve manufacturing services and design services. We have our own quality inspection company.

After-sales Service

Any quality problems within 12 months after purchase, Free replacement.

XINTAI Valve is a professional and one of the leading manufacturer worldwide for industry valves products, involving six ranges and thousands of varieties, for control valve, cryogenic valve, gate valve, globe valve, ball valve, check valve, butterfly valve, power station valve, oxygen valve, hydraulic control valve, thread valve and antibiotic valve.

Custom Valve Solutions for Almost Any Industry

XINTAI Valves has been a leading industrial manufacturer, providing high-quality casting ball, gate, globe, check, casting wedge valves.

Our Partnership

Petronas

PARCO

CNPC

SNPTC

CNOOC

SINOCHEM

sinope

Blog& News

Contact Us

If you want to get a quotation or more product details, please leave us a message.