Safety Valve Collection

The basic idea of a safety valve is to prevent accidents related to overpressure. When you're storing liquids or gasses in pressurized containers, you can encounter problems from time to time related to the pressure of those containers. And since this is obviously a huge hazard if it's not addressed, safety valves are used in all modern installations where pressurized tanks are involved, to act as a safeguard against incidents. If the pressure in a tank builds up too much, the valve is responsible for releasing the contents of the tank gradually until the pressure normalizes.

Safety Valves

Safety Valve Manufacturing

About XINTAI

XINTAI VALVE GROUP CO., LTD. was founded in 1998, is a professional valve manufacturing company that conjoins R&D, casting, development, production and sale. The Group's headquarters is located in the Longgang Airport New District, Wenzhou, and is centered on research and manufacturing technology.

The factory covers an area of approximately 30,800 square meters. The two major bases for casting were respectively located in the central industrial zone of Longwan District, Wenzhou, with an area of 9,800 square meters. Longwan Airport New Area Casting Base in Wenzhou, with an area of 28,000 square meters. The existing staff of 578 people, including high and mid-level engineering and technical personnel 58 people, mainly in oil, natural gas, chemical, power stations, metallurgy, national defense, water conservancy projects, pharmaceuticals and other fields.

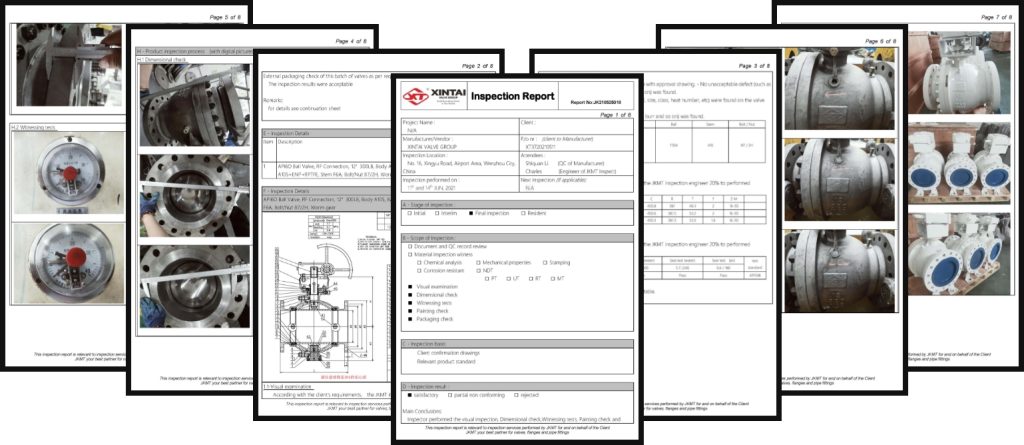

Safety Valve Inspection Report

We will issue an inspection report like this before all orders ship. The basic inspection steps include a visual examination, dimension check, witnessing test, painting check, packaging check, then issuing the finished test report. We can also carry out special tests according to customer requirements.

Our Team

We Will Serve You With The Best of Our Capacity By Expert Team

We are prestigious manufacturer and supplier of Industrial Casting Safety Valve in Wenzhou.

XINTAI is registered with the following governmental agencies:

American Petroleum Institute(API) No. 6D-1778

Quality Management System Certificate of Approval (ISO9001:2015)

Certificate of Quality System Approval(CE) No. HPiVS-IP1001-015-Q-04-00

Certification of Registration( OHSAS18001) No.86185710109S

We design, engineer and produce your tailor-made valves.

The Best Solution for Oil& Gas industry

Serving an impressive list of long-term clients with experience and expertise in industries.

Safety Valve -- a Controlling and Safety Device for Boilers and Pressure Vessels

Safety valves are an arrangement or mechanism to release a substance from the concerned system in the event of pressure or temperature exceeding a particular preset limit. The systems in the context may be boilers, steam boilers, pressure vessels or other related systems. As per the mechanical arrangement, this one get fitted into the bigger picture (part of the bigger arrangement) called as PSV or PRV that is pressure safety or pressure relief valves.

This type of safety mechanism was largely implemented to counter the problem of accidental explosion of steam boilers. Initiated in the working of a steam digester, there were many methodologies that were then accommodated during the phase of the industrial revolution. And since then this safety mechanism has come a long way and now accommodates various other aspects.

These aspects like applications, performance criteria, ranges, nation based standards (countries like United States, European Union, Japan, South Korea provide different standards) etc. manage to differentiate or categorize this safety valve segment. So, there can be many different ways in which these safety valves get differentiated but a common range of bifurcation is as follows:

- ASME

- Lift

- Flow controlled

- Balanced

- Power operated

- Full lift solid line

- Direct safety loaded

- Master

The American Society of Mechanical Engineers (ASME) I tap is a type of safety valve which opens with respect to 3% and 4% of pressure (ASME code for pressure vessel applications) while ASME VIII valve opens at 10% over pressure and closes at 7%. Lift safety valves get further classified as low-lift and full lift. The flow control valves regulate the pressure or flow of a fluid whereas a balanced valve is used to minimize the effects induced by pressure on operating characteristics of the valve in context.

A power operated valve is a type of pressure relief valve is which an external power source is also used to relieve the pressure. A proportional-relief valve gets opened in a relatively stable manner as compared to increasing pressure. There are 2 types of direct-loaded safety valves, first being diaphragms and second: bellows. diaphragms are valves which spring for the protection of effects of the liquid membrane while bellows provide an arrangement where the parts of rotating elements and sources get protected from the effects of the liquid via bellows.

In a master valve, the operation and even the initiation is controlled by the fluid which gets discharged via a pilot valve. Now coming to the bigger picture, the pressure safety valves based segment gets classified as follows:

- Thermal pressure valves (used for the provision of protection incase of excess pressure if the device experiences increase of temperature).

- Flow valves (come into picture where larger quantities of gases or liquids need to be released quickly to relive the growing pressure).

- Shut off valves (used to close a fluid or gas based line and to stop the flow of materials).

So all in all, pressure safety valves, pressure relief valves, relief valves, pilot-operated relief valves, low pressure safety valves, vacuum pressure safety valves etc. complete the range of safety measures in boilers and related devices.

What Should Be The Discharge Capacity Of A Safety Valve?

Safety valves have different discharge capacities. These capacities are based on the geometrical area of the body seat upstream and downstream of the valve. Flow diameter is the minimum geometrical diameter upstream and downstream of the body seat.

The nominal size designation refers to the inlet orifice diameter. A safety Valve's theoretical flowing capacity is the mass flow through an orifice with the same cross-sectional area as the valve's flow area. This capacity does not account for the flow losses caused by the valve. The actual capacity is measured, and the certified flow capacity is the actual flow capacity reduced by 10%.

A safety valve's discharge capacity is dependent on the set pressure and position in a system. Once the set pressure is calculated, the discharge capacity must be determined. Safety valves may be oversized or undersized depending on the flow throughput and/or the valve's set pressure.

The actual discharge capacity of a safety valve depends on the type of discharge system used. In liquid service, safety valves are generally automatic and direct-pressure actuated.

If you want to know more about the discharge capacity of a safety valve, continue reading this article.

What Are Safety Valves?

A safety valve is used to protect against overpressure in a fluid system. Its design allows for a lift in the disc, indicating that the valve is about to open. When the inlet pressure rises above the set pressure, the guide moves to the open position, and media flows to the outlet via the pilot tube. Once the inlet pressure falls below the set pressure, the main valve closes and prevents overpressure. There are five criteria for selecting a safety valve.

The first and most basic requirement of a safety valve is its ability to safely control the flow of gas. Hence, the valve must be able to control the flow of gas and water. The valve should be able to withstand the high pressures of the system. This is because the gas or steam coming from the boiler will be condensed and fill the pipe. The steam will then wet the safety valve seat.

The other major requirement for safety valves is their ability to prevent pressure buildup. They prevent overpressure conditions by allowing liquid or gas to escape. Safety valves are used in many different applications. Gas and steam lines, for example, can prevent catastrophic damage to the plant. They are also known as safety relief valves. During an emergency, a safety valve will open automatically and discharge gas or liquid pressure from a pressurized system, preventing it from reaching dangerous levels.

What Should Be The Discharge Capacity Of A Safety Valve?

The discharge capacity of a safety valve is based on its orifice area, set pressure, and position in the system. A safety valve's discharge capacity should be calculated based on the maximum flow through its inlet and outlet orifice areas. Its nominal size is often determined by manufacturer specifications.

Its discharge capacity is the maximum flow through the valve that it can relieve, based on the maximum flow through each individual flow path or combined flow path. The discharge pressure of the safety valve should be more than the operating pressure of the system. As a thumb rule, the relief pressure should be 10% above the working pressure of the system.

It is important to choose the discharge capacity of a safety valve based on the inlet and output piping sizes. Ideally, the discharge capacity should be equal to or greater than the maximum output of the system. A safety valve should also be installed vertically and into a clean fitting. While installing a valve, it is important to use a proper wrench for installation. The discharge piping should slope downward to drain any condensate.

The discharge capacity of a safety valve is measured in a few different ways. The first is the test pressure. This gauge pressure is the pressure at which the valve opens, while the second is the pressure at which it re-closes. Both are measured in a test stand under controlled conditions. A safety valve with a test pressure of 10,000 psi is rated at 10,000 psi (as per ASME PTC25.3).

The discharge capacity of a safety valve should be large enough to dissipate a large volume of pressure. A small valve may be adequate for a smaller system, but a larger one could cause an explosion. In a large-scale manufacturing plant, safety valves are critical for the safety of personnel and equipment. Choosing the right valve size for a particular system is essential to its efficiency.

How to Calculate the Discharge Capacity of a Safety Valve?

Before you use a safety valve, you need to know its discharge capacity. Here are some steps you need to follow to calculate the discharge capacity of a safety valve.

- Test Procedures

To check the discharge capacity of a safety valve, the safety valve should be installed in the appropriate location. Its inlet and outlet pipework should be thoroughly cleaned before installation. It is important to avoid excessive use of PTFE tape and to ensure that the installation is solid. The safety valve should not be exposed to vibration or undue stress. When mounting a safety valve, it should be installed vertically and with the test lever at the top. The inlet connection of the safety valve should be attached to the vessel or pipeline with the shortest length of pipe. It must not be interrupted by any isolation valve. The pressure loss at the inlet of a safety valve should not exceed 3% of the set pressure.

- Calculating The Discharge Capacity Of A Safety Valve

The sizing of a safety valve depends on the amount of fluid it is required to control. The rated discharge capacity is a function of the safety valve's orifice area, set pressure, and position in the system. Using the manufacturer's specifications for orifice area and nominal size of the valve, the capacity of a safety valve can be determined. The discharge flow can be calculated using the maximum flow through the valve or the combined flows of several paths. When sizing a safety valve, it's necessary to consider both its theoretical and actual discharge capacity. Ideally, the discharge capacity will be equal to the minimum area.

- Setting The Maximum Allowable Working Pressure

To determine the correct set pressure for a safety valve, consider the following criteria. It must be less than the MAAP of the system. Set pressure of 5% greater than the MAAP will result in an overpressure of 10%. If the set pressure is higher than the MAAP, the safety valve will not close. The MAAP must never exceed the set pressure. A set pressure that is too high will result in a poor shutoff after discharge. Depending on the type of valve, a backpressure variation of 10% to 15% of the set pressure cannot be handled by a conventional valve.

Contact Us

If you want to get a quotation or more product details, please leave us a message.