Stainless Steel Y Strainer Collection

In this modern society, valves are considered very useful components in different processes of manufacturing and systems of supply. If you look around you, values are part of every household. They are responsible for controlling the flow of all types of liquid, as well as the rate, pressure, volume and the direction. Not only that, valves control the direction of different gases, slurries and other dry materials through a pipe or any other type of passageway. Without these valves, there will be no automatic heat, public utilities or fresh water, and there will be no energy of any kind.

Strainer

Stainless Steel Y Strainer Manufacturing

The Best Solution for Oil& Gas industry

Serving an impressive list of long-term clients with experience and expertise in industries.

What Is Strainer Y Type?

Strainers are essential for filtration in pipelines. They help to remove debris as well as large particles from the liquid that flows in the pipeline.

Strainers are mostly used in petrochemicals as well as paint industries to filter unnecessary components. There are different types of strainers available in the market for industrial use.

Out of all the types, the most common is a Y-type strainer. This type of strainer is mostly used in liquid applications. It helps to protect the downstream equipment from debris and particles, thereby preventing clogging.

If you want to know more about the Y-type strainer, how it works, and its uses, continue reading this article.

What Is a Y-Type Strainer?

A Y-type strainer is a pipe fitting that separates solids from fluid. The Y-shape of the strainer is important in preventing debris from clogging pipes and reducing energy loss and productivity. This type of strainer has a Y shape and is used for pre-filtration or coarse filtration.

There are several different Y-type strainers on the market, including fabricated stainless steel, bronze, cast iron, and Y-types with a horizontal swivel. Depending on the size and design, a fabricated strainer can be a more economical option.

Some strainers can be used in vertical pipes that have a downward flow. It also comes with a blow-off connection so that it can be cleaned automatically when the pressure reaches the limit.

Y-type strainers are commonly used in pressurized, gas, and liquid lines. They are designed for infrequent clean-out and are best for small amounts of solid particulate. Because the Y strainer is able to filter very small amounts of material, they are often an economical option for removing particles from liquids.

How Does Y-Type Strainer Work?

A Y-Type Strainer is a type of strainer that protects downstream mechanical equipment from damage caused by sediment, rust, pipe scale, and extraneous debris. Most basket strainers are intended for horizontal piping applications.

However, a Y-Type Strainer is designed to be installed in the lowest position possible in order to minimize the chance of premature failure. It is available in a variety of sizes, mesh configurations, and end connections to meet the requirements of various applications.

Y-type strainers use perforated metal mesh as the straining element. The captured solids are then either exhausted into the atmosphere or flushed back into the system. A blow-off valve is mounted on the drain port of the strainer, allowing cleaning without disassembly. Its self-cleaning feature eliminates the need for shut-off valves and requires less maintenance.

Y-Type Strainers are usually used for steam and high-pressure applications. These types of strainers can withstand pressures as high as 400 bar g. While high steam temperatures complicate the use of strainers, the advantages of these devices make them a popular choice for these applications.

Features and Benefits of Y-Type Strainer

Y-Type Strainers are similar to T-Type Strainers, but they differ in some features. While both remove dirt from fluid systems, they serve different purposes. T-Type Strainers are generally larger, which makes them a better fit for pipeline applications. Y-Type Strainers, on the other hand, are generally smaller and more suited for applications where the filter must have quick access.

The Y-Type Strainer's filtration leg is attached at an angle to the Y-shaped body, giving it the shape of a 'Y.' It is generally used for high-pressure pipelines, but it can also be used in suction or vacuum conditions. However, the Y-type strainer's dirt holding capacity is less than other strainers, requiring more frequent cleaning. While this isn't an issue in steam systems, it can become a problem if the flow contains high amounts of debris or rust.

The Y-Type Strainer has the added benefit of being easy to purge without stopping the process. Its design was patented by the Henry Valve Company and was first made in 1953. The angled element of the Y strainer reduces the differential pressure and supports higher flow coefficients. In addition, the Y strainer can be purged without shutting down the process flow.

Another benefit is its ease of installation. Flanged Y strainers are often installed on horizontal pipes, but they can be installed vertically or horizontally as well. They are easy to clean, and the ability to adjust the flanged Y strainer to any length is convenient. They can also be installed vertically or horizontally. Stainless steel Y-Type Strainers can also be customized to suit your needs.

A Y-Type Strainer is commonly used in a variety of industries. The oil and petrochemical industry uses them. They offer excellent resistance to mechanical and thermal shock. Carbon steel Y-Type Strainers are also ideal for higher pressure applications. You may want to look for a strainer made of carbon steel to ensure that you get the right one. This is a great choice if you need a high-quality strainer that won't let you down.

A Y-Type Strainer is a versatile piece of equipment that offers endless customization possibilities. The design is entirely up to you, but before you purchase one, make sure you know what type of application you need it for. The Y-Type Strainer is best suited for industries where constant protection against debris is needed. For instance, it is used in steam applications, where high pressure is necessary. Its shape is ideal for this application.

A Y-Strainer can be installed in either a horizontal or vertical position. It has a blow valve installed in its cap to prevent the strainer from overheating and allowing you to clean it without shutting down your process. Y-Strainers are also cheaper and more compact than other strainers. However, their high-pressure capabilities make them more suitable for applications where continuous protection is needed.

How Do You Clean A Y-Type Strainer?

Y-strainers are difficult to clean visually, but they perform their function well. To clean them, you need to use differential pressure or a depressurizing system. A wire brush and wrench are required tools. A blow-down connection is also necessary to remove debris and clean the filter's filtered containment. Clean the strainer and replace it if necessary. This type of strainer is not universal, and you need to know your application before buying one.

Y-type strainers are most valuable in environments with high-pressure and constant contamination. They are also useful in vacuum or suction situations. These strainers tend to hold dirt less efficiently than basket-type strainers and therefore require frequent cleaning. They are not a problem for steam systems, but they can pose a problem for water systems with high levels of rust or debris.

You can manually clean the screens of your Y-Strainer by disassembling the cap or bushing. To do this, you need to shut off the water flow before cleaning the strainer. You can also remove the cap or blow-off valve to clear the screen. To clean the Y-Strainer, you need to remove the screen by unscrewing the bottom cap. To remove the clogged screen, you need to turn the flow off so you can clean the rest of the filter.

We design, engineer and produce your tailor-made valves.

About XINTAI

XINTAI VALVE GROUP CO., LTD. was founded in 1998, is a professional valve manufacturing company that conjoins R&D, casting, development, production and sale. The Group's headquarters is located in the Longgang Airport New District, Wenzhou, and is centered on research and manufacturing technology.

The factory covers an area of approximately 30,800 square meters. The two major bases for casting were respectively located in the central industrial zone of Longwan District, Wenzhou, with an area of 9,800 square meters. Longwan Airport New Area Casting Base in Wenzhou, with an area of 28,000 square meters. The existing staff of 578 people, including high and mid-level engineering and technical personnel 58 people, mainly in oil, natural gas, chemical, power stations, metallurgy, national defense, water conservancy projects, pharmaceuticals and other fields.

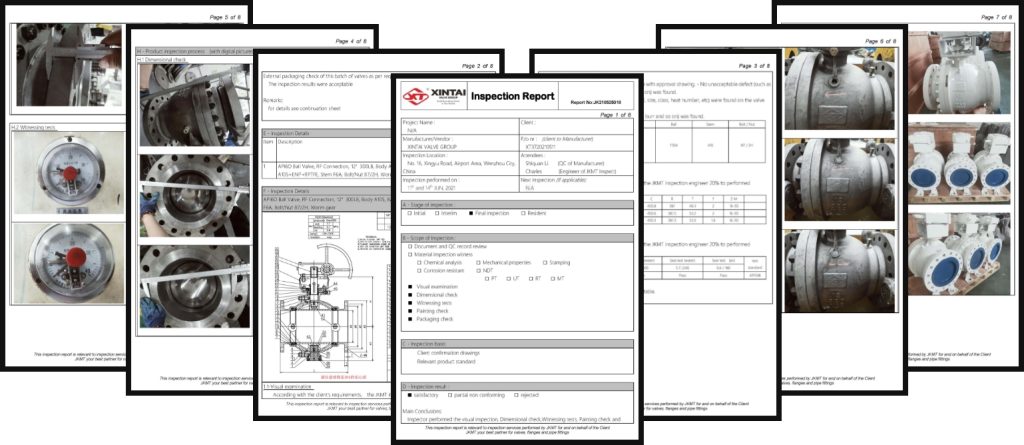

Stainless Steel Y Strainer Inspection Report

We will issue an inspection report like this before all orders ship. The basic inspection steps include a visual examination, dimension check, witnessing test, painting check, packaging check, then issuing the finished test report. We can also carry out special tests according to customer requirements.

Our Team

We Will Serve You With The Best of Our Capacity By Expert Team

We are a prestigious manufacturer and supplier of Stainless Steel Y Strainer in Wenzhou.

XINTAI is registered with the following governmental agencies:

American Petroleum Institute(API) No. 6D-1778

Quality Management System Certificate of Approval (ISO9001:2015)

Certificate of Quality System Approval(CE) No. HPiVS-IP1001-015-Q-04-00

Certification of Registration( OHSAS18001) No.86185710109S

Contact Us

If you want to get a quotation or more product details, please leave us a message.