Table of Contents

Toggle

Introduction

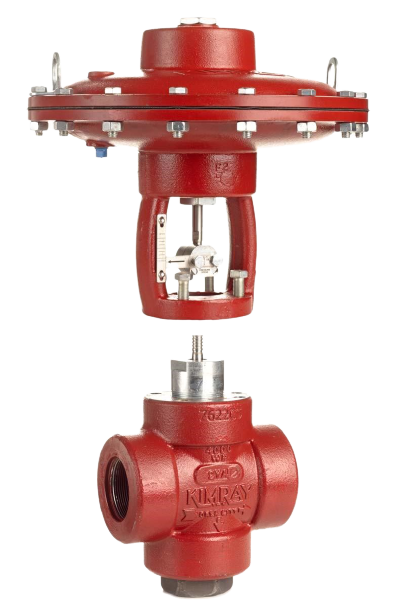

Pneumatic actuator gate valves are vital components in industries that require efficient control of fluid flow. These valves provide reliable and precise regulation of liquid or gas flow through pipelines. In this comprehensive guide, we will delve into pneumatic actuator gate valves, including their definitions, types, working principles, and key features. This information will help you gain a better understanding of these products and their applications.

Definitions and Types of Pneumatic Actuator Gate Valves

Pneumatic actuator gate valves are valves that use a pneumatic actuator to control the movement of a gate or wedge inside the valve body. These valves are designed to control fluid flow by raising or lowering the gate to open or close the flow passage. They come in various types, including:

- Rising Stem Gate Valves: Rising stem gate valves have a stem attached to the gate, which rises or lowers as the valve opens or closes. This design provides a visual indication of the valve’s position and allows for manual operation even when the actuator is not engaged.

- Non-Rising Stem Gate Valves: Non-rising stem gate valves have a gate that moves up and down within the valve body without the stem rising or lowering. These valves are ideal for applications with limited vertical space.

Working Principles of Pneumatic Actuator Gate Valves

Pneumatic actuator gate valves operate based on the principle of raising or lowering a gate or wedge to control fluid flow. When the pneumatic actuator receives a signal, it engages the valve, moving the gate to open or close the flow passage. The actuator provides precise control, allowing for accurate adjustments to regulate flow rates. If you want to know more about the Working Principles of Pneumatic Actuator Gate Valves, please click here.

Key Features and Advantages of Pneumatic Actuator Gate Valves

Pneumatic actuator gate valves offer several features that make them advantageous in fluid control applications. Some key features include:

- Excellent Flow Control

Pneumatic actuator gate valves provide precise control over fluid flow, allowing for accurate adjustments and modulation of flow rates. This makes them suitable for applications that require precise flow regulation.

- Bi-Directional Flow

Gate valves are capable of handling bi-directional flow, allowing for flow control in both directions. This versatility makes them suitable for various applications.

- Quick Operation

These valves have fast response times, enabling quick opening and closing of the valve, which is crucial in situations that require immediate flow control.

- Tight Shut-Off

Pneumatic actuator gate valves provide tight shut-off, minimizing leakage and ensuring reliable sealing.

Applications of Pneumatic Actuator Gate Valves

Pneumatic actuator gate valves find applications in industries such as oil and gas, water treatment, chemical processing, and more. They are commonly used in systems that require on/off control of flow, isolation of sections of pipelines, or regulation of flow rates.

Conclusion

Pneumatic actuator gate valves play a crucial role in ensuring precise fluid control in various industrial applications. With their robust construction, efficient operation, and reliable sealing, these valves provide an excellent solution for managing fluid flow in diverse settings. Whether you need to control the flow of liquids or gases, pneumatic actuator gate valves offer the reliability and performance you require. Explore the wide range of high-quality valve solutions available at Xintai Valves to find the perfect fit for your specific application.