A complete Guide to Industrial Ball Valve

Are you learning the essentials of industrial ball valves? Resources here cover everything from how ball valves work, to different materials, manufacturing processes, applications, production standards, and more.

Explore Industrial valves

Stay updated

A Complete Guide to Industrial Ball Valve

Learn about standard port, full port, V port, multi-port, true union, manually operated, motorized, and sanitary ball valves and their features, advantages, and disadvantages.

Frequently Asked Questions

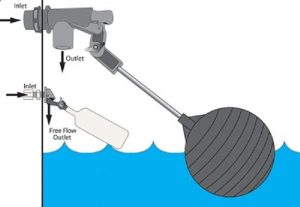

A floating ball valve is a valve that utilizes a ball as the mechanism to shut off the pipe’s cross-section and halt the fluid’s movement. This valve finds widespread use in various industries, such as oil and gas, water treatment, and chemical processing. The floating ball valve uses a hollow ball flooring in its control media. When the valve is open, the fluid flows through the valve body and around the ball.

However, when the valve is closed, the fluid pressure pushes the ball against the downstream seat, creating a tight seal that prevents the fluid from flowing through the valve. The ball is connected to a stem that allows for precise flow control by moving the ball slightly in an upstream or downstream direction. This type of valve provides bi-directional sealing, making it highly effective in controlling the flow of fluids. Overall, the floating ball valve is known for its reliability, long service life, and ability to provide a tight seal, making it a popular choice in various industrial applications.

LEARN MORE:

How Does A Floating Ball Valve Work?

Floating Ball Valve Vs Trunnion Ball Valve – What’s Their Difference?

A pneumatic valve actuator is a mechanism that utilizes compressed air to move a valve closure component, such as a plug, spring, or nut, to the specified position. Pneumatic actuators are dependable devices for controlling motion that convert energy into linear or rotary movement. They are frequently used in industrial settings where valves must be repeatedly opened and closed, especially in potentially hazardous environments.

Learn More: How Does A Pneumatic Valve Actuator Work?

Check and ball valves are essential in fluid systems that enable one-directional flow while preventing backflow. Similar in appearance but has unique functions and characteristics suited for specific purposes. Check valves are self-activating safety valves that only allow one flow direction for gases and fluids. Ball valves use a spherical ball to prevent reverse flow in gas systems or fluid applications where backflow could cause the pump or compressor to close. They are commonly used to protect compressors and pumps.

Learn More: What Are The Differences-Check Valve Vs. Ball Valve?

Key Terms -Material and Standard

A bronze industrial ball valve is a type of ball valve specifically designed for industrial applications. It is made of bronze material, which provides durability and corrosion resistance. Here are some critical points about bronze industrial ball valves:

- Typical services include low-pressure steam, compressed air, and non-potable water.

- Different types include one-piece, full-flow in-line, and two-piece valves.

- They are designed for bubble-tight shutoff, ensuring a tight seal at high pressures.

- Features reinforced PTFE seat rings, stainless steel stems, and balls for enhanced durability.

Forged valves are produced by shaping the metal in its solid form, using heat, tools, and dies to create the valve shape. Here are some advantages of forged valves:

- Minimal wasted material, as they are shaped in one solid piece.

- High strength and reliability make them suitable for high-temperature and high-pressure applications with minimal shrinkage, porosity, and cracks.

- Ideal for use in applications in oil and gas and power generation.

- Thinner walls, which reduce thermal fatigue when heated or cooled quickly.

Resouce: What is a Forged Valve?

API 608:

- API 608 is a standard for metal flanged, threaded, and welded ball valves.

- It covers specifications for ball valves, butterfly valves, and plug valves.

- API 608 is typically used for smaller-sized valves, with coverage up to NPS 20 (Nominal Pipe Size 20).

API 6D:

- API 6D is a valve standard that applies to piping and pipeline valves.

- It encompasses gate valves, globe valves, check valves, and ball valves.

- API 6D is more commonly used for long-distance pipeline engineering.

- It specifies differences from API 608 in terms of structure and function.

Learn More:

Here are some advantages of 3-way ball valves based on the search results:

- Simple structure with low volume.

- It can perform multiple functions in itself, such as mixing different media and diverting the direction of the flow of media, eliminating the need for extra accessories in systems where mixing and diversion of fluids are required.

- A 3-way ball valve ensures a steady flow rate compared to a 2-way ball valve.

- This feature enables various flow styles in a pipeline or system.

- Wear components, such as balls, ball seats, and stems, can be replaced quickly and independently, allowing the valve to remain in service for its intended lifecycle. At the same time, operators enjoy low long-term maintenance costs.