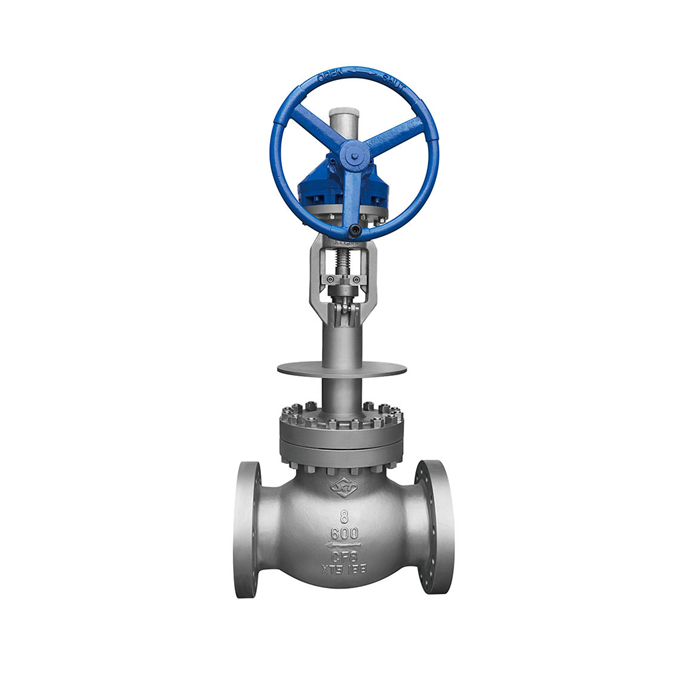

- TRUSTED, HIGH-QUALITY CUSTOM Cryogenic Valve

Cryogenic Valve Manufacturer from China

- Lightweight valves are preferable for cryogenic applications

- Conducive to limit the heat influx

- those that use lubricants appropriate for cold duty should be assembled in a clean environment.

Get A Quote & Consultation

Fill in our quote request form and we will reply to your message as soon as possible! Or send us an email at: hicyhu@xintaivalves.com