Electrically Operated Valves - Industrial Supply

You may be wondering what electrically operated valves are, and if so, you've come to the right place. These valves are designed to control fluid flow in a variety of applications, including industrial machinery. These valves are useful in many different types of applications, including in mobile machinery. The main difference between these valves and manual ones is the type of control they use.

Electrically Operated Valves

Electrically Operated Valves Manufacturing

The Best Solution for Oil& Gas industry

Serving an impressive list of long-term clients with experience and expertise in industries.

What Are Electrically Operated Valves?

Industrial valves can be operated manually as well as automatically. In manual operation, you have to physically open and close the valve to control the flow.

However, automatic valves are operated automatically. These are electrically operated valves. These valves come with an electric actuator. To use these types of valves, you can simply use the On/Off button. It saves you from the hassle of manually opening and closing valves.

Electrically operated valves are hydraulic or pneumatic valves that come with an endpoint switch. You can easily control these valves. If you want to know more about electrically operated valves, continue reading this article.

What Are Electrically Operated Valves?

You may be wondering what electrically operated valves are, and if so, you've come to the right place. These valves are designed to control fluid flow in a variety of applications, including industrial machinery. These valves are useful in many different types of applications, including in mobile machinery. The main difference between these valves and manual ones is the type of control they use.

In terms of operation, electrically operated valves have an actuator that controls the position of the valve. Generally, these valves operate by opening and closing. However, in some cases, the valve's power supply may fail for a period of time, in which case the actuator will remain stationary. A typical example of this is an air compressor shut down. If an air compressor fails, the actuator will remain stationary until power is restored.

Most electrical actuators are designed to close upon power failure. However, in some applications, the valve needs to open to prevent overheating. The power source of the actuator is critical. The NEMA rating of an electric valve can help you determine which type is best suited for your specific application.

The main differences between mechanical and electrically operated valves are their mounting methods. Mechanical actuators have a flange on the valve shaft and a shaft that connects to the actuator. In many cases, the larger the flange, the higher the torque needed to operate the system. Similarly, an electric actuator must be mounted securely to ensure proper torque transmission. The best way to mount an electrical valve actuator is to use sturdy industry standards for the mounting process.

How Do Electrically Operated Ball Valves Work?

These valves are controlled by electric motors, which allow for manual, semi-automatic, and even automatic operation. In general, they are used for open-close functions, and the motors themselves allow you to position the valve at any point in its travel. This is possible due to the motor's reversible high-speed drive and gear train, which reduce the speed and increase the torque at the stem. The motors' direction of rotation determines the direction of disk motion and vice versa.

When choosing an actuator, you should consider three primary factors: emissions, automation capabilities, and cost. Because of tighter environmental regulations, electric actuators are increasingly popular. They don't release emissions and don't require a high-pressure gas supply. Pneumatic actuators, on the other hand, are often powered by compressed air or a vapor recovery unit. As a result, they're the most energy-efficient option.

In addition to their ease of operation, electric actuators can also be remotely controlled. Today, more than a million of these actuators are in use around the world. In fact, according to European Industrial Forecasting Ltd., nearly 75% of oil and gas valves and 30% of all valves are powered by an electrical motor.

The Benefits of Using Electrically Operated Gate Valves

There are several benefits of using electrically operated valves. Some of these benefits include Quiet, Non-toxic, Fast actuation, and energy efficiency. To learn more about the advantages of electrically operated valves, read on.

- Quiet Operation

A solenoid valve can be noisy, particularly in a quiet environment like a hospital. The clicking noise it creates can distract from the medical instrument's design, and it can cause patients to become uneasy. To mitigate this, some manufacturers are now using a special plunger that provides metal-to-elastomer contact. But if you can't find a solenoid valve that does not make this noise, there are a few alternatives. Instead, you can use electrically operated valves. Compared to manual systems, electrically operated valves can operate large valves more quickly. They can also release and distribute fluids. On top of that, these valves will not make any screeching noises. It is perfect for areas where there is noise regulation.

- Non-Toxic

Using electrically operated valves offers many benefits. They can be operated without the presence of engineers and can be shut down when the process is finished. Additionally, they can operate for 99 hours, which makes them a great choice in dangerous environments. The additional non-toxic benefits of these valves include the safety of the workers who operate them. They can also improve production efficiency, which can speed up construction projects. An electrically operated valve uses an electric motor to generate torque to open or close a valve. These valves are quiet, energy-efficient, and can even operate off of batteries. These valves are made of non-toxic materials and will not harm the environment.

- Energy Efficient

There are many benefits to switching to more energy-efficient electrically operated valves. These valves can help reduce energy consumption and create strategic advantages for the end-user. While the most immediate benefit will be a decrease in electricity costs, the benefits are also transferable, as the reduced cost can be passed on to the end consumer. Besides saving money, they can also increase public awareness of the machine. These valves can save up to 50% of energy. Electricity consumption can vary widely between valves, so choosing the right one for your application will make the biggest difference.

- Fast Actuation

Electric actuators are used in hydraulic systems to control valves. These valves are available in different designs, including a mechanical type and an electrical type. Electric motors can be manual, semi-automatic, or automatic. These valves have a range of positioning functions, including fully opening and closing. The motors are usually reversible and connected through a gear train, which reduces their speed and increases the torque on the stem. The direction of the motor rotation determines the motion of the disk. These valves can also be semi-automatic or manual. These valves offer fast actuation. As you don't have to manually open or close the valve, it will help you to save time. The electric mechanism of this type of valve helps in fast actuation.

We design, engineer and produce your tailor-made valves.

About XINTAI -Industrial Supply

XINTAI VALVE GROUP CO., LTD. was founded in 1998, is a professional valve manufacturing company that conjoins R&D, casting, development, production and sale. The Group's headquarters is located in the Longgang Airport New District, Wenzhou, and is centered on research and manufacturing technology.

The factory covers an area of approximately 30,800 square meters. The two major bases for casting were respectively located in the central industrial zone of Longwan District, Wenzhou, with an area of 9,800 square meters. Longwan Airport New Area Casting Base in Wenzhou, with an area of 28,000 square meters. The existing staff of 578 people, including high and mid-level engineering and technical personnel 58 people, mainly in oil, natural gas, chemical, power stations, metallurgy, national defense, water conservancy projects, pharmaceuticals and other fields.

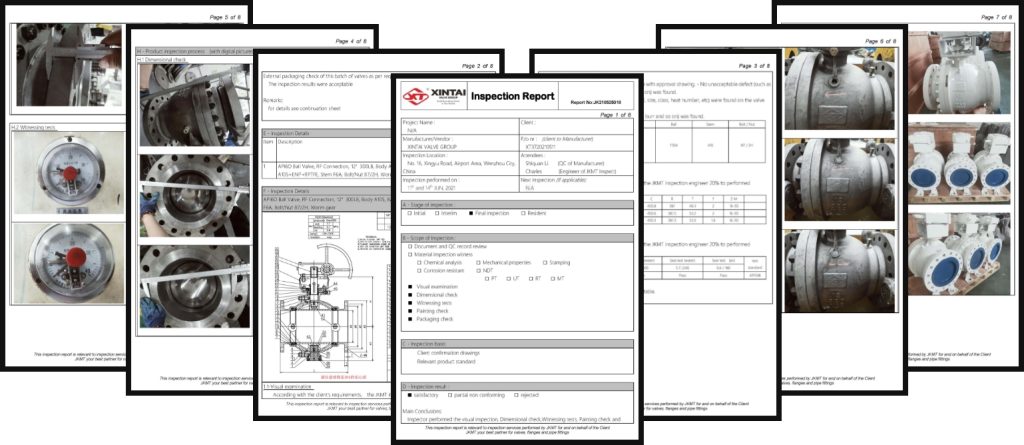

Electrically Operated Valves Inspection Report

We will issue an inspection report like this before all orders ship. The basic inspection steps include a visual examination, dimension check, witnessing test, painting check, packaging check, then issuing the finished test report. We can also carry out special tests according to customer requirements.

Our Team

We Will Serve You With The Best of Our Capacity By Expert Team

We are prestigious manufacturer and supplier of Electrically Operated Valves in Wenzhou.

XINTAI is registered with the following governmental agencies:

American Petroleum Institute(API) No. 6D-1778

Quality Management System Certificate of Approval (ISO9001:2015)

Certificate of Quality System Approval(CE) No. HPiVS-IP1001-015-Q-04-00

Certification of Registration( OHSAS18001) No.86185710109S

Contact Us

If you want to get a quotation or more product details, please leave us a message.