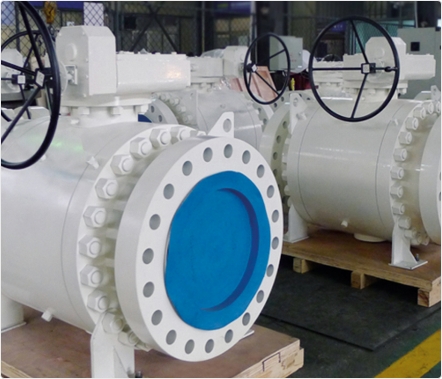

Forged Floating Ball Valves

Floating ball valves have different ways of working. One is to increase the flow of fluid through the valve by partially turning the ball disc in one direction. In the other, the ball is rotated 90 degrees to face the flow of media. This system also creates an orifice that changes size as upstream pressure acts on the valve. As a result, the floating ball valve can either open or close in either direction. This guide contains crucial factors that will assist you to select the best ball valve that will serve you for many years without having to incur regular replacement costs.

Floating Ball Valves

Floating Ball Valve Manufacturing

The Best Solution for Oil& Gas industry

Serving an impressive list of long-term clients with experience and expertise in industries.

What Is a Floating Ball Valve?

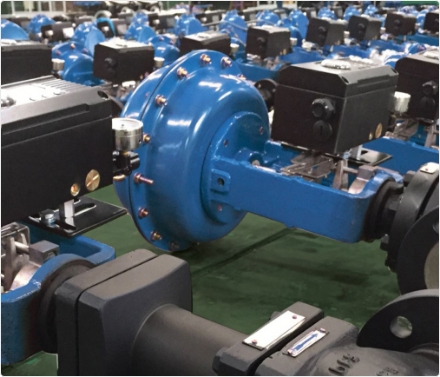

Floating ball valves (Click here to learn more) are a popular type of ball valve and have a variety of applications. This type of valve comes with a floating or suspended ball that moves due to the pressure to control the flow. Their main function is to control the flow of liquids in pipelines.

A floating ball valve works by sandwiching a hollow ball between two cupped seats. The ball moves upstream when onstream pressure increases. When the pressure drops, the ball moves downstream. The resulting seal prevents the liquid from leaking out. This valve is typically operated by a lever, gear, or pneumatic/hydraulic actuator. A floating ball valve features a seat that seals when a liquid flow is reversed. What's more, there is a forged floating ball valves. This kind of ball valve has a floating ball supported by two valve seats. Forged floating ball valves are also available in Double Block & Bleed designs and in custom configurations such as cryogenic extended bonnet or with special actuation.

The Working Principle of a Floating Ball Valve

Floating ball valves are used in various applications to control the flow of a fluid. The principle behind their operation is simple: a ball contains a hole in the center. This hole serves as the flow opening when the cross-section of the fluid flow path and the bore are coplanar. If the two are not coplanar, flow is throttled. Floating ball valves may consist of a solid ball with a consistent opening diameter throughout the structure. This makes fluid flow through the valve smooth and steady.

A floating ball valve is most common in applications where the pressure is low. This type of valve is suited for a range of fluids, including gases and liquids. However, it cannot be used when the pressure on the upstream side is high because the ball directly absorbs the fluid's gravity.

A floating ball valve is operated by a mechanical actuator. The stem moves to turn the ball disc to face the flow of media. A ring connects the stem to the actuator. Depending on the actuator, it can be operated manually by an electric motor, pneumatically, or hydraulically. Its working principle is similar across all housing types. But the housing design determines the cost of ownership and repair.

We design, engineer and produce your tailor-made valves.

About XINTAI VALVES Manufacturer

XINTAI VALVE GROUP CO., LTD. was founded in 1998, is a professional industrial ball valve manufacturing company that conjoins R&D, casting, development, production and sale. The Group's headquarters is located in the Longgang Airport New District, Wenzhou, and is centered on research and manufacturing technology.

The factory covers an area of approximately 30,800 square meters. The two major bases for casting were respectively located in the central industrial zone of Longwan District, Wenzhou, with an area of 9,800 square meters. Longwan Airport New Area Casting Base in Wenzhou, with an area of 28,000 square meters. The existing staff of 578 people, including high and mid-level engineering and technical personnel 58 people, mainly in oil, natural gas, chemical, power stations, metallurgy, national defense, water conservancy projects, pharmaceuticals and other fields.

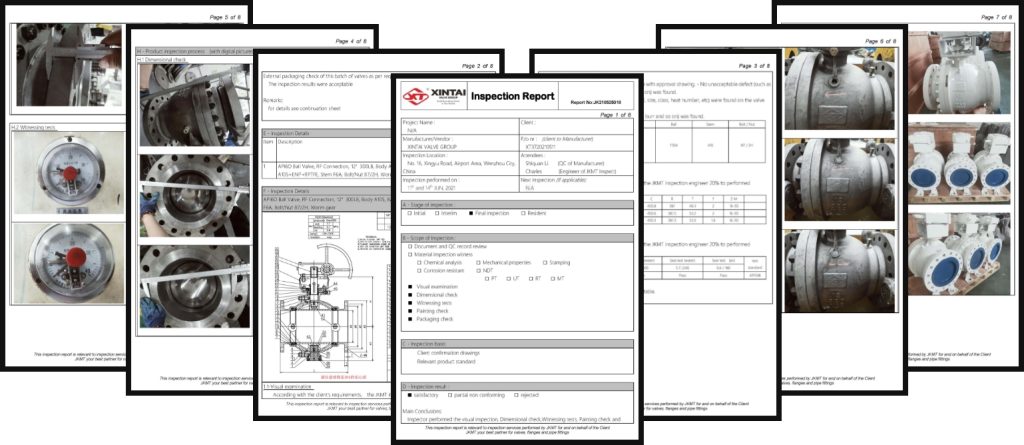

Ball Valve Inspection Report

We will issue an inspection report like this before all orders ship. The basic inspection steps include a visual examination, dimension check, witnessing test, painting check, packaging check, then issuing the finished test report. We can also carry out special tests according to customer requirements.

Our Team

We Will Serve You With The Best of Our Capacity By Expert Team

We are prestigious industrial ball valve manufacturer and supplier of Industrial Forged Floating Ball Valves in Wenzhou.

XINTAI is registered with the following governmental agencies:

American Petroleum Institute(API) No. 6D-1778

Quality Management System Certificate of Approval (ISO9001:2015)

Certificate of Quality System Approval(CE) No. HPiVS-IP1001-015-Q-04-00

Certification of Registration( OHSAS18001) No.86185710109S

Contact Us

If you want to get a quotation or more product details, please leave us a message.