Basket Strainer - Industrial Supply

You might be wondering what a Basket strainer is and why it's used in the manufacturing process. The answer is simple: a basket strainer helps to ensure that the fluids are free of any solid components. These strainers work as a filter and help to clean the fluids of unnecessary solid materials. These baskets are available in various different types, i.e., single-cylinder, double cylinder, pleated style, and multi-cylinder.

Basket Strainer

Industrial Basket Strainer Manufacturing

The Best Solution for Oil& Gas industry

Serving an impressive list of long-term clients with experience and expertise in industries.

How Is Industrial Basket Strainer Useful?

Strainers and filters are extremely important in industries. They are widely used to keep the swimming pool clean and filter debris like leaves, insects, etc. Apart from that, filters are also used in industrial applications to filter fluids effectively.

A basket strainer can be used for a variety of purposes. In the paint manufacturing industry, a basket strainer can ensure that the paint is smooth and free of solids. Its filtration systems help guarantee smooth and consistent paint application since lumps and particles in the liquid will negatively affect the application.

You can purchase a basket strainer that features multiple cylinders or a duplex design, which allows you to clean one basket while keeping the flow of the other. A Basket Strainer is a durable piece of equipment, but it should still be cleaned regularly to ensure its effectiveness.

If you want to know more about a basket strainer and its uses, continue reading this article.

Click here to view more Industrial Basket Strainer.

What Is A Industrial Basket Strainer?

You might be wondering what a Basket strainer is and why it's used in the manufacturing process. The answer is simple: a basket strainer helps to ensure that the fluids are free of any solid components. These strainers work as a filter and help to clean the fluids of unnecessary solid materials. These baskets are available in various different types, i.e., single-cylinder, double cylinder, pleated style, and multi-cylinder.

A basket strainer is mostly used in the chemical and paint industries. It helps to make sure that the paint produced is smooth and free of unwanted solids. Filtration systems help to ensure that the paint is smooth and consistent, and these filters are a vital part of the process. As a result, there are many different uses for a basket strainer.

A basket strainer is a type of filter that is typically connected to a pump's suction. They filter out debris and larger particles that would otherwise clog the pipes. They also help to prevent damage to the internal components of the pump. These filters must be cleaned regularly to prevent clogging. If they are clogged, they will interfere with fluid flow. To prevent this problem, you should clean the basket strainer as often as possible.

A basket strainer can be used in a variety of industries. Basket strainers are commonly used in the mechanical, ceramic, paint, and biofuel industries. They are available in standard and deep sizes. Depending on the system, you can choose between stainless steel or brass models. To prevent clogging, it is important to choose a basket strainer with the appropriate connection size.

How Does Industrial Basket Strainer Work?

A basket strainer works by trapping small particles that fall through a mesh screen. It measures the particle size based on its perforation area, which is expressed as a number of openings per linear inch. Small particles may be allowed to pass through the screen, but larger ones will not. The mesh is usually made of stainless steel. Mesh sizes can range from 16 to 100. Large particles may be captured by mesh strainers, while small ones may be lost by blowdown.

A basket strainer is a useful filtration device for a wide variety of applications. For example, it is commonly used in the paint manufacturing process. This is because paint must be smooth and free of unwanted solids. Filtration systems ensure that paint is uniformly smooth and free of lumps and particles, which can affect its application. They can filter a variety of materials and can protect downstream equipment.

The fluids enter the basket strainer through the inlet and move out through the outlet. The mesh screen of the strainer traps all the large objects or debris in the fluid and helps clean fluid to pass through the outlet. However, as more and more debris is collected in the basket, the outlet flow decreases. Once the pressure exceeds a certain valve, a blowing port is opened in the basket, which helps to blow out all the debris and maintain adequate inlet and outlet pressure. This is how a basket strainer works.

The Applications and Benefits of Using a Industrial Basket Strainer

A basket strainer is a piece of machinery used in pipeline systems for filtering liquids and other solids. Its primary function is to remove unwanted solids and particles from the flowing stream. Because it has a single chamber, a basket strainer is not suited for progressive processes because a stoppage in operation is required for changing the basket.

A basket strainer is used in different pipeline applications and may be required for different functions. The type of liquid flow, pressure, temperature, size and frequency of cleaning should all be considered when choosing the right one. If there are multiple strainer baskets in a pipeline, the duplex style of a basket strainer is a great choice because it can hold two different strainer trays while allowing for easy washing.

A basket strainer is a great choice for continuous applications that require high pressure and fast flow. It can be easily maintained with a cover that allows you to access the strainer element and replace, clean, or repair it. Duplex strainers are particularly useful since the process does not stop while the strainer is being serviced. They are also more cost-effective than other types of strainers.

A basket strainer can be made of stainless steel or another material. Stainless steel is a popular material for basket strainers because it is corrosion-resistant and rust-proof. It is also easy to clean. The advantages of using a basket strainer include greater straining surface area compared to plate strainers. Furthermore, a basket strainer offers less pressure loss through the strainer, allowing for a faster flow rate.

A basket strainer can help remove particulate matter and foreign objects from the water. The interlaced mesh screens that are built into its housing protect downstream equipment and save you from expensive repairs. Stainless steel material offers enhanced corrosion resistance and durability, which is essential for industrial applications.

Using a basket strainer is a simple way to prevent contamination in any system. The mesh is designed to trap and remove larger particles. These particles can be harmful to downstream components and potentially pollute valuable end products. They are commonly installed in pools and pipelines to eliminate these problems.

The benefits and applications of a basket strainer are varied. Its main function is to remove dirt and debris from a flowing liquid. A basket strainer is a vessel that is enclosed in housing. Its housing allows the basket to be immersed in a washing mixture and scrubbed with a brush. It is important to check for leakage around all connections before using a basket strainer.

We design, engineer and produce your tailor-made valves.

About XINTAI

XINTAI VALVE GROUP CO., LTD. was founded in 1998, is a professional valve manufacturing company that conjoins R&D, casting, development, production and sale. The Group's headquarters is located in the Longgang Airport New District, Wenzhou, and is centered on research and manufacturing technology.

The factory covers an area of approximately 30,800 square meters. The two major bases for casting were respectively located in the central industrial zone of Longwan District, Wenzhou, with an area of 9,800 square meters. Longwan Airport New Area Casting Base in Wenzhou, with an area of 28,000 square meters. The existing staff of 578 people, including high and mid-level engineering and technical personnel 58 people, mainly in oil, natural gas, chemical, power stations, metallurgy, national defense, water conservancy projects, pharmaceuticals and other fields.

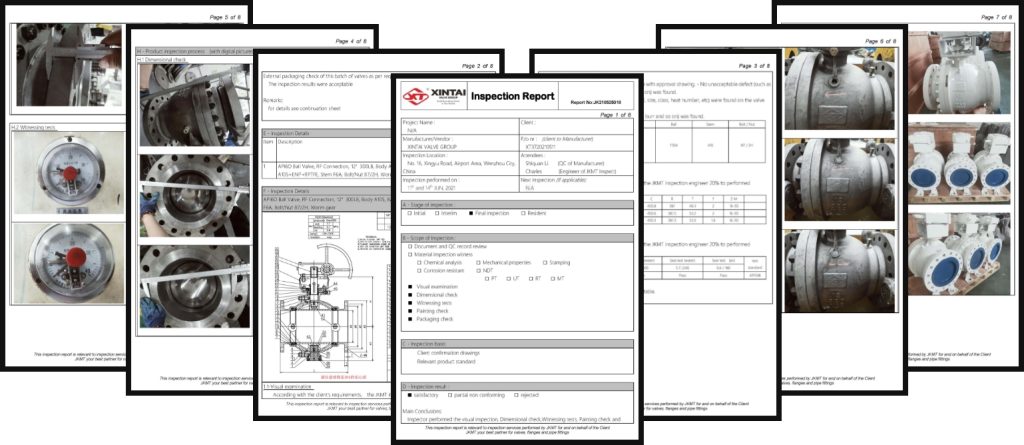

Basket Strainer Inspection Report

We will issue an inspection report like this before all orders ship. The basic inspection steps include a visual examination, dimension check, witnessing test, painting check, packaging check, then issuing the finished test report. We can also carry out special tests according to customer requirements.

Our Team

We Will Serve You With The Best of Our Capacity By Expert Team

We are a prestigious manufacturer and supplier of Industrial Basket Strainer in Wenzhou.

XINTAI is registered with the following governmental agencies:

American Petroleum Institute(API) No. 6D-1778

Quality Management System Certificate of Approval (ISO9001:2015)

Certificate of Quality System Approval(CE) No. HPiVS-IP1001-015-Q-04-00

Certification of Registration( OHSAS18001) No.86185710109S

Contact Us

If you want to get a quotation or more product details, please leave us a message.