Safety Valve Collection

The safety valve is a type of valve that opens automatically when the pressure is high. This helps to relieve excessive pressure and prevent any accidents. These valves are made of different types of material as per the pressure handling capability. The material of the safety valve base affects the response pressure. To avoid this, some safety valves feature a rupture disk in front of the valve. These disks are also resistant to pressures. In order to avoid these problems, some manufacturers include a KUB V safety valve, which has a smooth metal surface.

Spring Load Safety Valve

Spring Load Safety Valve Manufacturing

The Best Solution for Oil& Gas industry

Serving an impressive list of long-term clients with experience and expertise in industries.

What Is The Material Of A Safety Valve Disk?

The safety valve (View safety valve information on wikipedia) is a type of valve the opens automatically when the pressure is high. This helps to relieve excessive pressure and prevent any accidents. These valves are made of different types of material as per the pressure handling capability.

The material of the safety valve base affects the response pressure. To avoid this, some safety valves feature a rupture disk in front of the valve. These disks are also resistant to pressures. In order to avoid these problems, some manufacturers include a KUB V safety valve, which has a smooth metal surface.

A disc is made from a variety of materials. While most are made from rubber, some are made of metal or plastic. Refractory metal, nitrile rubber, and PEEK are some of the more common materials. A disk that's made from a polymer, for example, may be better suited for applications where high pressure can be used. A safety valve disk is an important component for maintaining pressure in a building. Discs are available in a variety of sizes, from three millimeters to four feet.

If you want to know more about a safety valve and what materials a safety valve disc is made of, continue reading this artifice.

What Is A Safety Valve?

A safety valve is a type of pressure regulator that opens and closes quickly in case the pressure inside a system increases and automatically returns to its closed position once the safe pressure level is reached. The disc of a safety valve is arranged for rapid opening and closing, with a second chamber formed by a shroud around the outside diameter of the disc. Safety valves have several advantages over conventional standard valves.

When choosing a safety valve, make sure you choose the type that meets your needs. Safety valves are often used in the energy sector, where a system failure can cause a fire or explosion. The valve can be adjusted to the desired level, but you must reduce the inlet pressure to less than 90% of its opening pressure. This way, the valve won't open while you're making adjustments.

Safety valves are also known as safety relief valves, and they can also act as relief valves. In some cases, safety relief valves are used in liquid and gas systems. These valves are often installed in steam lines and gas lines because they are crucial for protecting your plant against over-pressurization. If they fail to close properly, the pressure can lead to a disastrous situation, which can be catastrophic for the equipment and people inside the system.

What Is A Disc In A Safety Valve?

Generally, a safety valve comes with a solid metal disc that seals the valve to prevent leakage into the atmosphere. This prevents process emissions from getting into the atmosphere, which satisfies EPA regulations. The disc is a pressure-containing component of a safety valve. It holds the pressure in the valve up to a certain limit.

The disc is one of the most important components of a safety valve. It is the opening and closing mechanism of the valve. When the disc moves up, the valve opens, thereby letting out the materials. When the disc sets in place, the flow stops. As a safety valve is used for the high-pressure application, the disc plays a very important role.

These discs are made from different types of materials. If you want a high-quality and long-lasting safety valve, you need to invest in a disc made from strong and sturdy material. Different material offers different discharge capacity, so you need to choose the right material for the disc.

What Is The Material of a Safety Valve Disc?

The safety valve comes with an internal disc to control the pressure. These discs are made of different types of materials. Here are the most common material used to make safety valve discs.

- Bronze

If you're wondering why the disc on safety valves is made from Bronze material, you've come to the right place. Safety valve discs are generally made of bronze material, although they can be made of many other materials as well. Bronze is one of the most durable materials used in safety valve discs, making them highly durable and reliable. Bronze valves are used on systems that have low SWP. But if you're working with lower pressures, then you can go for Class 150 valves. Bronze valves shall also meet ASTM standards for their body and stem materials. A bronze safety valve disc is made from two components - a piston and a spring bonnet.

- Cast Iron

The safety valve disc is typically made of cast iron. Cast iron is an extremely strong material that goes through intense vibrations. The disadvantage of this material is that it is not ductile, meaning that it can't be bent. This is a disadvantage, but it is one that safety valve manufacturers are willing to take, as it is the cheapest material for safety valve discs. There are also other advantages to cast iron, including its lower cost.

- SG Iron

When comparing safety valves, SG iron or cast-iron material is often preferred. Although there are some differences between the two, their properties are almost identical. SG iron is most commonly used in European valves, and cast steel is most often used for higher pressure valves.

- Cast Steel

Safety valve discs are also made of cast iron. It is mostly used on high-pressure valves. Cast steel is commonly used to make process-type valves. The body is made of cast steel along with other materials. Even though cast steel is not strong, it can still be used to make the disc inside a safety valve.

- Austenitic Stainless Steel

The safety valve disc is made of austenitic stainless steel. The valve body is made of this material, along with the yoke nine and stem 4. The stem is typically made of a carbon steel material, while the rest of the valve is made of austenitic stainless steel. The difference between the two types is their allowable stress levels. The maximum stress level for austenitic stainless steel is 10 kg/mm2. It is mostly used to make valves for pharmaceutical, food, and clean steam application industries.

We design, engineer and produce your tailor-made valves.

About XINTAI

XINTAI VALVE GROUP CO., LTD. was founded in 1998, is a professional valve manufacturing company that conjoins R&D, casting, development, production and sale. The Group's headquarters is located in the Longgang Airport New District, Wenzhou, and is centered on research and manufacturing technology.

The factory covers an area of approximately 30,800 square meters. The two major bases for casting were respectively located in the central industrial zone of Longwan District, Wenzhou, with an area of 9,800 square meters. Longwan Airport New Area Casting Base in Wenzhou, with an area of 28,000 square meters. The existing staff of 578 people, including high and mid-level engineering and technical personnel 58 people, mainly in oil, natural gas, chemical, power stations, metallurgy, national defense, water conservancy projects, pharmaceuticals and other fields.

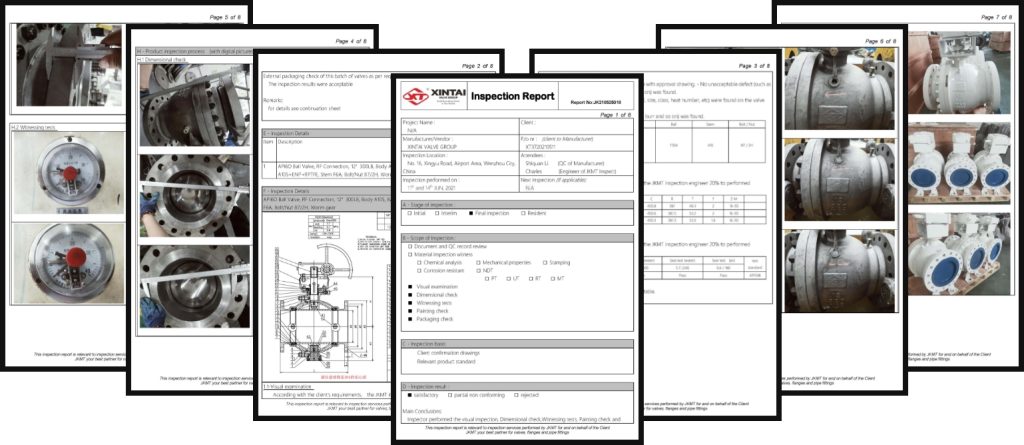

Spring Load Safety Valve Inspection Report

We will issue an inspection report like this before all orders ship. The basic inspection steps include a visual examination, dimension check, witnessing test, painting check, packaging check, then issuing the finished test report. We can also carry out special tests according to customer requirements.

Our Team

We Will Serve You With The Best of Our Capacity By Expert Team

We are prestigious manufacturer and supplier of Spring Load Safety Valve in Wenzhou.

XINTAI is registered with the following governmental agencies:

American Petroleum Institute(API) No. 6D-1778

Quality Management System Certificate of Approval (ISO9001:2015)

Certificate of Quality System Approval(CE) No. HPiVS-IP1001-015-Q-04-00

Certification of Registration( OHSAS18001) No.86185710109S

Contact Us

If you want to get a quotation or more product details, please leave us a message.