Advantages of Using Jacketed Valves

If you're considering investing in a new valve, you should know about type of jacketed valves. They are a good choice for the following reasons. First, they save energy. Some of these benefits include lower operating costs and longer service life. Second, they provide improved thermal performance in extreme conditions. Finally, they minimize energy losses.

Jacketed Valve

Jacketed Valves Manufacturing

The Best Solution for Oil& Gas industry

Serving an impressive list of long-term clients with experience and expertise in industries.

What Is A Jacketed Valve?

If you're thinking about buying a new valve for your process, you might be wondering about how the jacket works. Basically, this type of valve has a sleeve and jacket that is placed within its body.

Depending on the application, the jacket can have a different shape and size than the valve itself. Jackets can either be insulated or non-insulated, depending on the desired temperature or flow rate.

Jacketed valves are typically available in two or three-way configurations. Standard jacketed valves are flanged while oversized valves are welded. These valves have a wide variety of material options for the jacket.

Some jackets are even made from superalloys for critical operations. The jackets of jacketed valves can be stainless steel, aluminum, or carbon. You can even choose a custom material for your valve if your requirements dictate it.

If you want to know more about jacketed valves and jacketed valve manufacturers ( Click here to read blog “Jacketed Valves Manufacturers and Suppliers in the USA”, continue reading this article.

What Is A industrial Jacketed Valve?

A jacketed valve is a piping system that utilizes an external media to control a process fluid. The jackets are constructed in the body of the valve, and they can vary in shape and size. These valves have a jacket-like covering on top. Depending on the desired flow and temperature control, these valves may also utilize a metal-based sealing system. The media used in jacketed valves can include steam, thermal oils, water, or refrigerants.

The jacketed valves are designed for chemical applications where absolute control is required over a specified temperature range. The jacket is constructed to maintain temperature and viscosity consistency and minimize the risk of seizing or crystallization of the flow media. These valves have oversize flanges that allow bolting clearance. These valves are typically operated by a manual, gear unit, or electrical actuator.

Generally, jacketed valves come in one or more sizes. They can be made from Cast Carbon Steel (WCB), Stainless Steel (SS304-316-316L-316M), and Hastelloy alloy. Jacketed valves can also be cast from Duplex Steel (D2205) or Hastelloy (HC-22/HC276). The jackets may be welded to the body or cast into the valve.

What Are the Different Types of Jacketed Valve Design?

When you think of a Jacketed Valve, you might think about the hot jacketed valve, cold jacketed valve, and partial-welded jacketed valve. However, these are not all the same. This article will explain what each of these types is and how they differ.

- Hot Jacketed Valve

A Hot Jacketed Valve is a device that maintains a continuous flow of fluid through a pipeline. The jacket is made up of solidified materials, and the valve body is enclosed in a flange that is one size larger. This allows for proper bolting clearance. The material used for the flange is usually different than that of a standard flanged valve. A Hot Jacketed Valve has several advantages over a standard flanged valve. The Hot Jacketed Valve can be manufactured from several different materials. For example, the material can be cast carbon steel (WCB), SS304-316L-316M, or a hot oil-based alloy. It can also be manufactured from stainless steel, bitumen, or coal tar.

- Cold Jacketed Valve

The Cold Jacketed Valve is designed to control the temperature and flow of media within the system. The valve body is lined with a jacket which is made of a material that is either cast or welded to the valve's outer layer. This protective covering is essential for maintaining the temperature of the process media and for minimizing the fluid's stickiness. The primary purpose of a Cold Jacketed Valve is to control the temperature of the flowing fluid. This prevents the plant from reaching the temperature limit it cannot tolerate and allows it to continue operating. The design of the Cold Jacketed Valve makes it safe to operate while minimizing the risks of fire and abrasion. Cold Jacketed Valve can be custom-made as per customer requirements.

- Partial Welded Jacketed Valve

A Partially Welded Jacketed Valve covers only the center of the valve body, leaving room at the flanges for bolts. This type of valve is a low-cost option for service temperatures below 200°F. It also provides reliable insulating for pipe fluids. Its design and materials make it an excellent choice for low-temperature applications. Full jacketing is another option and can be welded onto any valve type with standard or oversize flanges. The jacket material can be made of a variety of materials, including stainless steel or nickel or other exotic materials.

Advantages of Using Jacketed Valves

If you're considering investing in a new valve, you should know about jacketed valves. They are a good choice for the following reasons. First, they save energy. Some of these benefits include lower operating costs and longer service life. Second, they provide improved thermal performance in extreme conditions. Finally, they minimize energy losses.

Jackets are available in two types: clamp-on or weld-on styles. While weld-on jackets are better for most applications, they are susceptible to failure, especially when the valve is not installed correctly. Moreover, incorrect application processes may result in deformation and warping of the valve seat. This can lead to the valve no longer functioning properly as an isolating valve.

In terms of design, jacketed valves offer numerous advantages. In addition to being more durable, they also prevent the seizing and crystallization of flow media. This type of valve prevents the spreading of a failure throughout the process. And it is especially effective for liquid sulfur and bitumen. The valve eliminates pockets. So if you need a valve that keeps a fluid liquid, consider purchasing a Jacketed Ball Valve.

One major advantage of jacketed valves is their versatility. They can be customized to meet specific needs. A four-way valve can be plugged with an additional port. A five-way valve is an example of this, but it can also be used as a multi-valve group. If you need a valve with several ports, you can select a jacketed valve. These valves are able to handle a wide range of fluids, and they can be used for a variety of applications.

You can use it for low or high-temperature applications. These valves can be used to control the flow of hot media as well as cold media. Most industries use these types of valves for hot oil, hot water, and steam. They can also be used for chilled water and cold water.

We design, engineer and produce your tailor-made valves.

About XINTAI

XINTAI VALVE GROUP CO., LTD. was founded in 1998, is a professional valve manufacturing company that conjoins R&D, casting, development, production and sale. The Group's headquarters is located in the Longgang Airport New District, Wenzhou, and is centered on research and manufacturing technology.

The factory covers an area of approximately 30,800 square meters. The two major bases for casting were respectively located in the central industrial zone of Longwan District, Wenzhou, with an area of 9,800 square meters. Longwan Airport New Area Casting Base in Wenzhou, with an area of 28,000 square meters. The existing staff of 578 people, including high and mid-level engineering and technical personnel 58 people, mainly in oil, natural gas, chemical, power stations, metallurgy, national defense, water conservancy projects, pharmaceuticals and other fields.

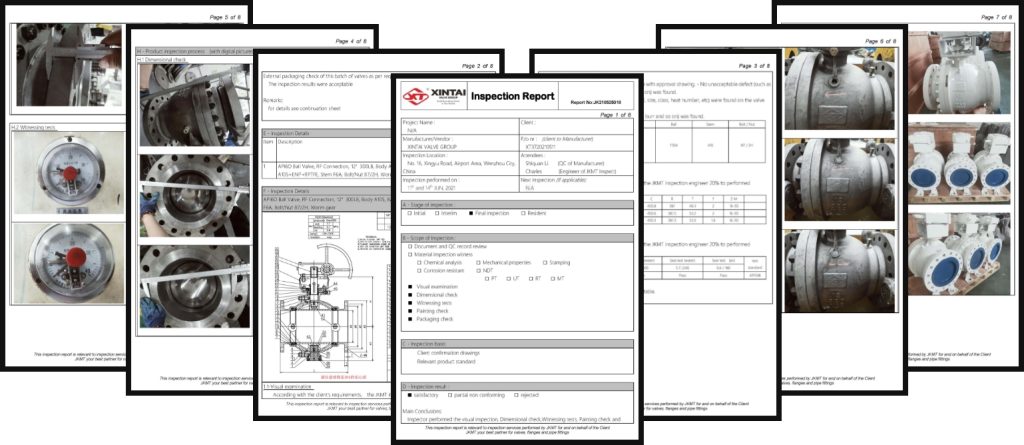

Jacketed Valves Inspection Report

We will issue an inspection report like this before all orders ship. The basic inspection steps include a visual examination, dimension check, witnessing test, painting check, packaging check, then issuing the finished test report. We can also carry out special tests according to customer requirements.

Our Team

We Will Serve You With The Best of Our Capacity By Expert Team

We are prestigious manufacturer and supplier of Jacketed Valves in Wenzhou.

XINTAI is registered with the following governmental agencies:

American Petroleum Institute(API) No. 6D-1778

Quality Management System Certificate of Approval (ISO9001:2015)

Certificate of Quality System Approval(CE) No. HPiVS-IP1001-015-Q-04-00

Certification of Registration( OHSAS18001) No.86185710109S

Contact Us

If you want to get a quotation or more product details, please leave us a message.