Y Strainer Collection

A Y strainer is a straight-through fitting installed on the return line to your chiller. Make sure to install it with the flow direction in mind. If you're using a 20-mesh Y strainer, the inner mesh traps contaminants and other particles and prevents them from getting back into the chiller. Keeping the interior of the chiller clean, protects pumps and internal components.

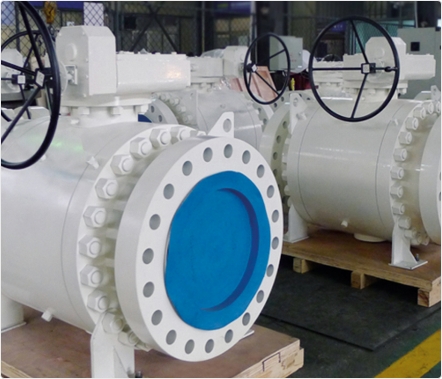

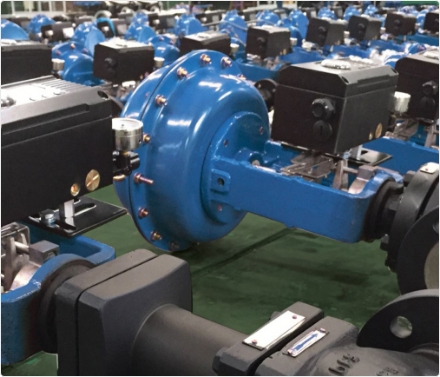

Ball Valves

Y Strainer Manufacturing

About XINTAI VALVES Manufacturer

XINTAI VALVE GROUP CO., LTD. was founded in 1998, is a professional industrial ball valve manufacturing company that conjoins R&D, casting, development, production and sale. The Group's headquarters is located in the Longgang Airport New District, Wenzhou, and is centered on research and manufacturing technology.

The factory covers an area of approximately 30,800 square meters. The two major bases for casting were respectively located in the central industrial zone of Longwan District, Wenzhou, with an area of 9,800 square meters. Longwan Airport New Area Casting Base in Wenzhou, with an area of 28,000 square meters. The existing staff of 578 people, including high and mid-level engineering and technical personnel 58 people, mainly in oil, natural gas, chemical, power stations, metallurgy, national defense, water conservancy projects, pharmaceuticals and other fields.

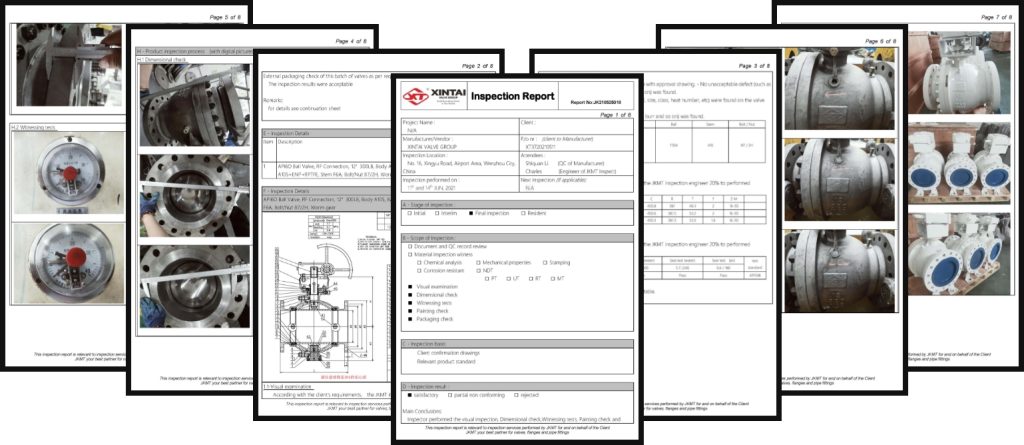

Y Strainer Inspection Report

We will issue an inspection report like this before all orders ship. The basic inspection steps include a visual examination, dimension check, witnessing test, painting check, packaging check, then issuing the finished test report. We can also carry out special tests according to customer requirements.

Our Team

We Will Serve You With The Best of Our Capacity By Expert Team

We are prestigious industrial Y Strainer manufacturer and supplier of Industrial Casting Ball Valves in Wenzhou.

XINTAI is registered with the following governmental agencies:

American Petroleum Institute(API) No. 6D-1778

Quality Management System Certificate of Approval (ISO9001:2015)

Certificate of Quality System Approval(CE) No. HPiVS-IP1001-015-Q-04-00

Certification of Registration( OHSAS18001) No.86185710109S

We design, engineer and produce your tailor-made valves.

The Best Solution for Oil& Gas industry

Serving an impressive list of long-term clients with experience and expertise in industries.

How Does a Y Strainer Work?

A Y strainer is a type of filter that separates debris at a level determined by the openings of the elements. The separated material is retained within the element chamber until it is cleaned. In addition to this, a valve that is attached to the cover of the element opens in response to the differential pressure between the process fluid and the atmosphere. These filters can be installed vertically within a section of piping if the flow is downward.

A Y-strainer filters out mechanical impurities in a medium. They can filter out even the tiniest of solids. This feature also protects the pipes of equipment against abrasion and malfunction. The Y-strainer is made up of two ends, with one allowing liquid to pass and the other containing waste. Water that is to be treated enters through the inlet while impurities are trapped on the stainless steel screen, generating a pressure difference.

In determining the size of the Y strainer, start by comparing the Cv value, which represents the entire design of the strainer. A cheaper Y strainer may have a smaller OAR and a lower Cv value than its more expensive counterpart. The length of the element chamber should be appropriate for the application, as shorter ones will reduce material usage while maximizing performance. The right Y strainer will meet your needs for its function and be more affordable than its counterparts.

The Working Principle of a Y Strainer

The Y strainer works by catching impurities in the liquid, blocking them from flowing through the mesh, and preventing them from reentering the system. It protects the main components of a system by preventing the impurities from reaching the parts that need filtration. A Y strainer works in high-velocity systems and is capable of withstanding pressures of up to 6,000 psi.

Cleaning a Y strainer requires a small amount of time. Cleaning the device requires the removal of the Y strainer cover plate, which must be removed to clean it. To reassemble the device, follow the reverse disassembly process. Y strainers usually come with a variety of different types of seals. The most common type is PTFE, which is suitable for both high and low temperatures. Other types of seals include Fluoro Rubber Seal, which is also known as FPM or FKM, and EPDM, which offers different chemical resistance and temperature range.

When buying a Y strainer, it is important to select one with the right mesh size. Choosing the mesh size is crucial because too small an opening can result in a large pressure drop and additional system burden. In addition, choosing a Y strainer with a filter screen that has too small of an opening will allow larger particles to pass through, affecting the overall performance and lifespan of downstream equipment.

Contact Us

If you want to get a quotation or more product details, please leave us a message.