Table of Contents

ToggleIn HVAC industries, different types of valves are used to control as well as manage the flow of material and maintain adequate pressure.

HVAC stands for Heating Ventilation and Air Conditioning. It consists of central air conditioners, boilers, heat pumps, rooftop units, furnaces, packaged units, and chillers. These systems work on water and steam as coolant gases which are passed through valves.

There are different types of valves used in HVAC systems. HVAC valves help to control the flow of fluids as well as gases. It helps to run the system smoothly.

If you want to know more about the different types of valves used in HVAC, continue reading this article.

What Is HVAC System?

If you are interested in the workings of your HVAC system, then you must first know what it is. HVAC systems are designed to move air through a series of pipes that warm it up or cool it down, as well as remove humidity. Depending on the system, the air may be directed to various parts of the house, and some may direct it directly into the space.

The heating element, or furnace, is the most important part of an HVAC system and occupies the most space. It uses various types of heat sources, such as solar energy, heat pumps, and electric resistance, to produce heat. In the cooling process, a unit called an evaporator coil funnels cold air throughout the house.

In order to maintain the temperature inside a room, you must ensure that both the supply and return registers are functional. The HVAC system may include other components, including ventilation, dehumidifiers, and air purifiers.

Types of Valves Used in HVAC Systems

The following article covers the types of valves that are used in HVAC Systems. You’ll be much happier with your HVAC system when you know more about it!

A control valve is a mechanical device that initiates a change in the flow of fluids within a system. Its shape is similar to that of a butterfly or ball. They are all equipped with actuators that move a modulating element, which can be a butterfly or ball, to control fluid flow. A Control valve has several types of actuators, and each type has its own purpose and mechanism of operation. There are various types of HVAC control valves available. Each one is designed to cater to different fluid and system requirements. It has different characteristics, such as throttling and blocking. Some of these valves are designed for high-pressure fluids, while others have specific corrosive properties.

A check valve is an automatic device that allows one liquid to flow through another while blocking the other fluid. A check valve works by using a pressure differential to open and close. If the pressure on the inlet side is greater than the pressure on the outlet side, the valve will close. The mechanisms for closing a check valve depend on the type of valve, but in general, they do not require any human intervention. A check valve is also used in HVAC systems to prevent water hammer, a phenomenon where fluid flows in one direction but then flows the other way.

- Double Block And Bleed Valves

A double block and bleed valve is a type of regulating valve. The purpose of these valves is to isolate the upstream and downstream flow of process fluids by closing one of them and opening the other. A third valve is placed in the cavity created by the two isolation valves. The valves can be used for a number of purposes, including flow diverting and sampling. These valves are used to control process flow, as well as sampling and maintenance. They can be used for positive and negative isolation. Positive isolation is achieved by isolating the operational portion of a plant from its equipment, pressure gauges, and level gauges. A valve containing two blocks would be closed and drained. The bleed valve is in a double block, and bleed assembly is used to release trapped air between the two block valves.

- Pressure Relief Valves

Pressure relief valves are devices that open and close when the pressure inside a fluid system becomes too high. They are made of diaphragms or balls, which close orifices. The spring-loaded mechanism is attached to a housing and is adjustable. Increasing the pressure on the spring increases the set-pressure limit of the relief valve. There are two types of pressure relief valves: conventional and proportional. Conventional valves are spring-loaded, and the former is normally located on the vessel’s top. The latter is used when a building needs to vent out the refrigerant. Neither of these is suitable for all environments, but they are suitable for commercial and industrial settings.

- Balancing Valves

You can buy a balancing valve from a variety of manufacturers, and some of them even provide electronic measurement equipment that measures the pressure loss across the valve. Once you have this information, you can calculate the flow rate based on the valve’s position. This type of valve is used in the chiller’s evaporator outlets of the HVAC system. They often provide a report containing the measured flow rates of the various systems.

- Butterfly Valves

Butterfly valves are used in a wide variety of applications, including the HVAC system. They provide bubble-tight shutoff of liquids and are suitable for both industrial and commercial use. Typical applications include boiler, chiller and cooling tower isolation, change-over systems, bypass, and process control.

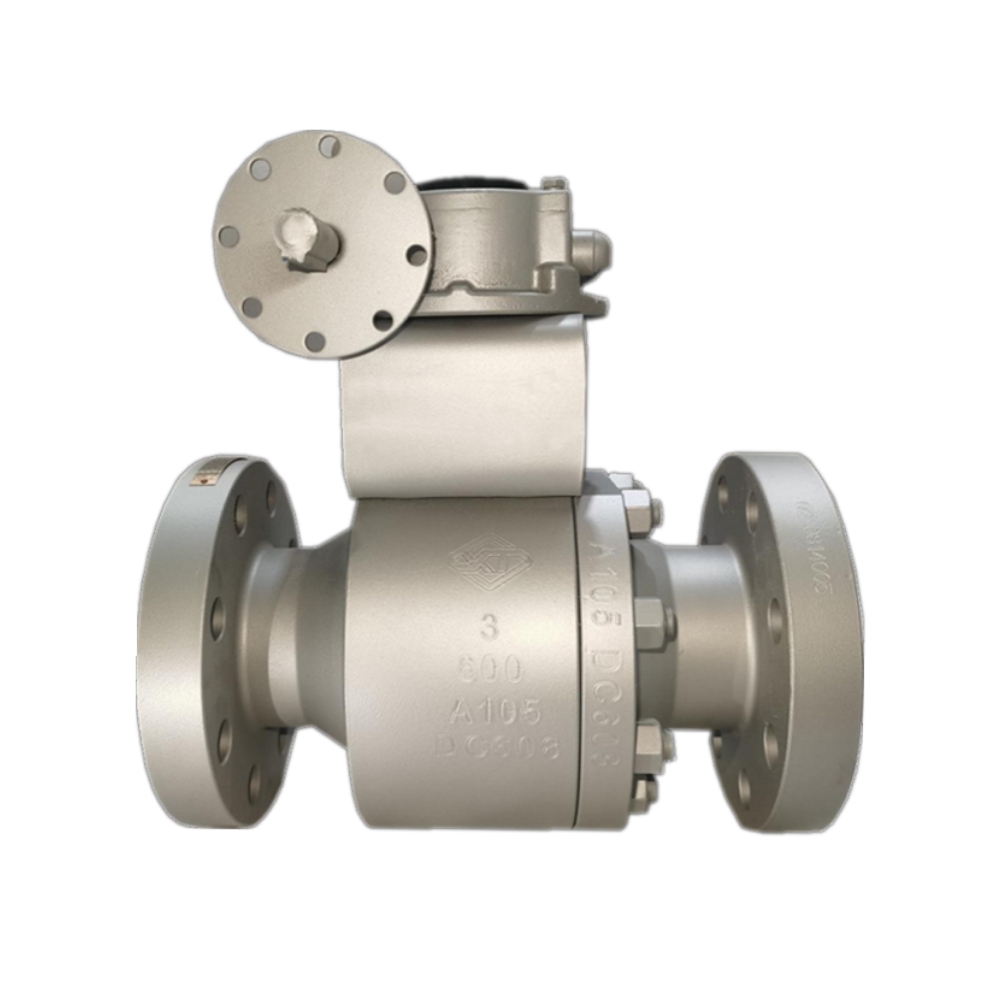

If you’re looking for a way to save on energy costs, ball valves may be the answer. These devices are used in a wide variety of applications, including HVAC and refrigeration systems. Despite their name, ball valves are not only small but also lightweight. They’re also ideal for use in sub-critical systems.

- Float Valves

There are a number of ways to use float valves in your HVAC system. These include the management of water levels in major industrial plants. They are also used to control the temperature of a room or other environment. Float valves are commonly used in HVAC systems because of their high reliability and easy installation. They are typically used for both balancing and controlling the flow of water.